What’s the most effective remedies for preventing thermal runaway propagating in a battery pack. We look at the options.

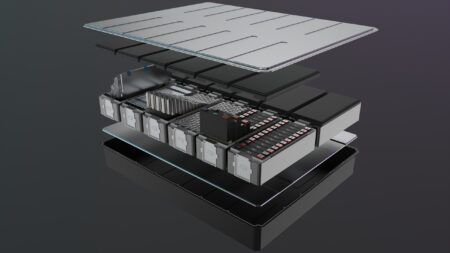

By now, the industry is largely aware of the risk of battery thermal runaway in battery electric vehicles. Thermal runaway is a safety issue involving the rapid failure and energy release from the battery that can lead to severe fire and explosion. In modern electric vehicles, the battery pack contains numerous small battery cells, all electrically interconnected. Heat is generated when a battery is either charging or discharging. The faster the charge (or discharge) rate, the more heat that is generated. Battery thermal runaway occurs when there is damage to the integrity of the battery cell. This can lead to an unintended “short circuit.” The result is a sudden amount of heat, which melts the battery components and generates noxious gases.

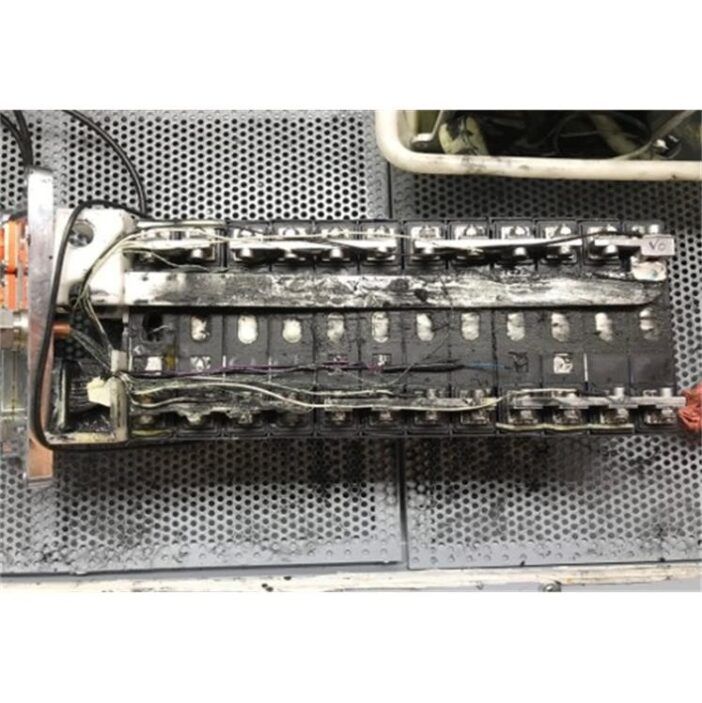

The problem with battery thermal runaway is that the damage may extend beyond a single battery cell. When one cell fails, it heats up the neighbouring cells, which quickly causes a chain reaction of thermal runaway events that spreads throughout the battery pack, often leading to sudden explosions and fire.

OEMs rely on various methods to cool the battery. A common method is to use a water-glycol mixture that flows through a metal plate or ribbon in close contact to the battery cells. This indirectly keeps the battery cool, much like a radiator in a traditional internal combustion engine vehicle.

Other indirect thermal management designs include aerogel panels, foams, and cooling plates. The problem with these indirect methods is that, while they may slow or partially contain the propagation of thermal runaway, the safety risk persists.

There is a safer solution for battery cooling – direct immersion cooling. With this approach, the battery assembly is directly immersed in a dielectric fluid. Dielectric fluids are nonconductive, ensuring that the numerous electrical connections within the battery pack are fully compatible without the risk of failure. Direct immersion effectively suppresses battery thermal runaway. If one battery cell fails, the immersion fluid contains the damage, helping to quickly dissipate the heat generated and avoiding failure in the other battery cells, along with improved safety, there are performance benefits with direct immersion of the battery. However, not all direct immersion fluids are the same. The few direct immersion fluids that have been commercialized up to this point tend to be hydrocarbon-based fluids with minimal additive content. The addition of the right additive technologies in the formulation allows for improved material compatibility, better anti-static properties, and optimized viscosity. The result is a fluid that improves battery performance, delivers safer operation, and ensures longer fluid life.

The difference in comparing the performance to an industry-standard synthetic fluid vs. a battery pack immersed in Lubrizol’s specially formulated dielectric fluid is clear [see images above]. We should expect to see a strong consumer preference for faster charging times as BEVs become increasingly popular, and direct immersion of the battery via a battery thermal management (BTM) fluid offers an intriguing solution for meeting this demand.