Proventia has developed resilient battery solutions tailored for the unique demands of NRMM industry

Recognizing the unique demands and diverse operating conditions of non-road mobile machines (NRMM), Finnish company Proventia has leveraged its three decades of experience in machinery to innovate in the NRMM battery industry.

“The path to a net zero future in NRMM isn’t uniform; it encompasses hybrid systems, fuel cell technologies, and renewable fuels,” says Jari Granath, product manager of Proventia Batteries. “Batteries, particularly, are integral to hybrid and fuel cell systems, yet they face more challenging conditions in NRMM than in the automotive industry.”

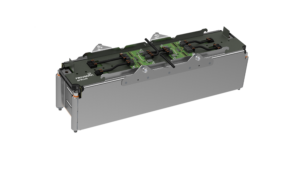

To address these challenges, Proventia has developed a robust battery module employing lithium titanate oxide (LTO) technology. LTO’s superior safety, stability and reliability make it ideal for the challenges of NRMM environments.

The high C-rates of LTO batteries, ranging from 10 to 40, facilitate rapid charging and discharging, essential for NRMM applications. These batteries have a lifespan 10 to 20 times longer than other lithium battery types and they operate safely from -30°C to +60°C.

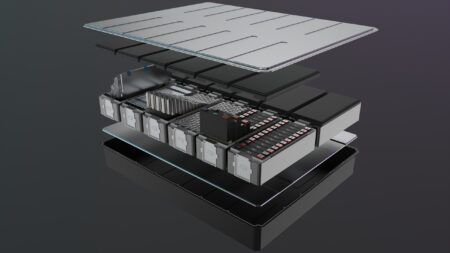

Proventia’s battery solutions range from 48V low voltage systems up to 800V high voltage packs, each featuring a modular design for customizable capacity and voltage. The batteries play a pivotal role, for example, in peak power management for high-voltage hybrid systems, enabling the use of smaller combustion engines, and thereby reducing fuel consumption and ownership costs. In fuel cell applications, Proventia batteries provide a rapid load response, enhancing the efficiency and lifespan of the fuel cell.

The Proventia low voltage batteries are ideal for mild hybrids and improving exhaust after treatment’s (EAT) thermal management, especially as emission reduction targets become more stringent (Tier 5/ Stage VI). Proventia’s distinct approach to battery engineering is evident in its in-house engineered ePRO battery systems. Standard ePRO battery packs feature robust construction, providing remarkable resilience against harsh elements. The core battery module is key in developing high-power, customized battery packs for applications where off-the-shelf solutions cannot be used.

“Our advantage lies in our comprehensive knowledge of non-road mobile machinery,” says Granath. “Our long experience in the NRMM OEM industry translates to our battery development. We utilize advanced simulation methods to design, integrate, and control our batteries to align with our client’s machinery. This streamlines the engineering process.”

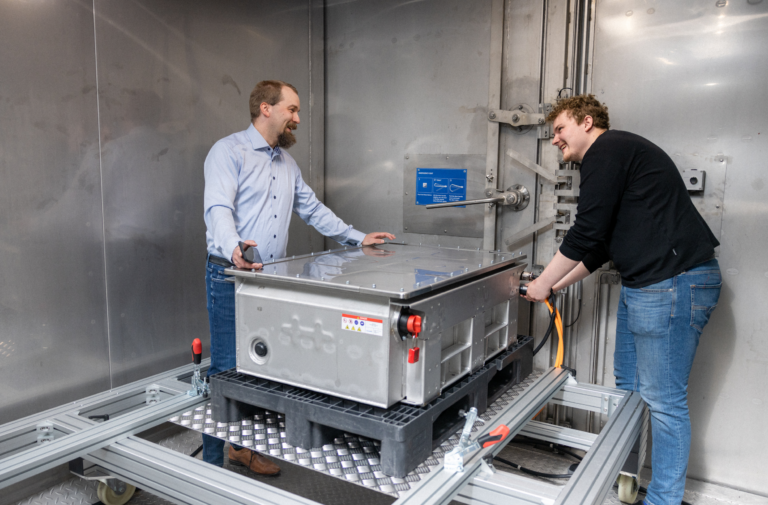

Furthermore, Proventia has an in-house testing center, including a climate-controlled battery pack testing laboratory and combustion engine test cells, for comprehensive hybrid system testing. This approach, which combines battery engineering using simulations and testing is essential in advancing battery technology for the NRMM industry. It enables the creation of specialized high-performance battery solutions for the unique, harsh environments of machines in agricultural, construction, and material handling industries for instance.