Electric vehicles (EVs) are transforming the transportation industry, offering a cleaner, more efficient, and more sustainable way to move people and goods. However, not all EVs are created equal, and different applications require different powertrain solutions. For commercial vehicles, such as buses and heavy-duty (HD) trucks, performance, reliability, and cost are critical factors that determine the success of electrification.

A common misconception is EVs don’t need transmissions, since electric motors can provide instant torque over a wide speed range. However, this is not the case for many electric commercial vehicles, which must deal with heavy loads, steep hills, and highway speeds. A single-speed or direct-drive system either requires a very large and expensive motor to provide enough power and torque to the wheels or limits the performance and range of vehicles with a reasonably sized motor.

A multi-speed transmission, however, can expand the operating range of the motor, reduce its size (and cost) and improve the efficiency and performance of the vehicle. A multi-speed transmission also enables improved regenerative braking performance, recovering more energy from the vehicle’s motion and reducing wear and tear on the foundation brakes. While transmissions are beneficial for EVs, they don’t need as many gear ratios as conventional vehicles with an internal combustion engine (ICE). This is because electric motors have a much faster and smoother torque response than

ICEs and can provide continuous peak torque over a much wider speed range. This means fewer gears are required to cover the same operating range, and the vehicle can spend more time in the optimal gear for efffficiency and performance. Eaton has leveraged its expertise in gear design and shifting technology to develop EV transmissions that offffer the optimal number of gears for difffferent applications, ranging from two-speed to six-speed.

There are three main types of EV powertrain architectures which can be used for commercial vehicles: central drive, e-axle, and direct drive. Eaton’s EV transmissions are currently focused on central drive architectures, which consist of a chassis-mounted motor and transmission connected to the axle by a driveshaft. This architecture offers several advantages: low complexity, proven reliability, ease of integration, flexibility of motor selection, and excellent battery packaging space. Eaton’s EV transmissions can also be adapted to the e-axle architecture, which integrates the motor and gearbox into the rigid axle, offering the best battery packaging space availability. The direct drive architecture, which eliminates the transmission and connects the motor directly to the wheels, is not recommended for heavy-duty applications, as it requires a large and expensive motor and limits the performance and range of the vehicle.

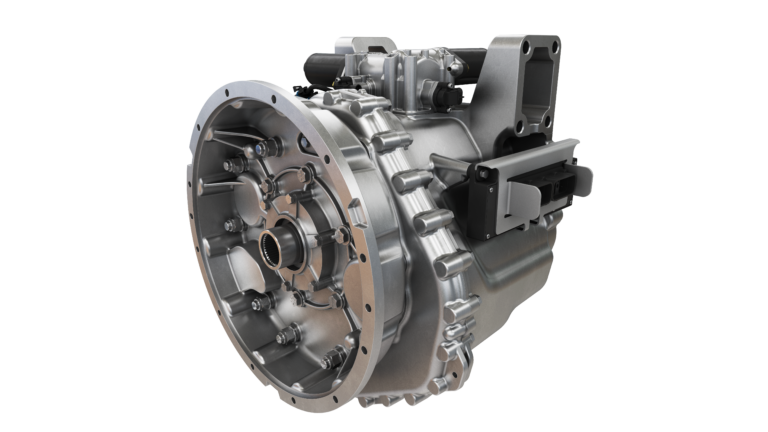

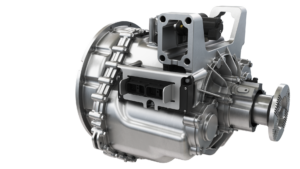

Eaton’s HD four-speed EV transmission has a maximum torque capacity of 2600Nm and a maximum input speed of 5000rpm, making it suitable for vehicles with a gross combination weight of up to 43 tons. It also features an all-aluminum enclosure, helical gearing, a transmission-mounted control module and an integrated electric actuation system, resulting in a lightweight, high-efficiency and low-noise transmission. Eaton’s proprietary shift control logic ensures smooth and seamless gear changes, while the rear PTO option enables auxiliary power for accessories. The HD four-speed EV transmission also offers easy integration with multiple motor options, thanks to the SAE #2 motor adapter. The HD four-speed EV transmission is currently in the B-sample stage, with the start of production planned for 2024