Electric mobility needs reliable high-voltage measurement solutions to ensure the operational safety of on-board installations and charging infrastructure

Modern electric vehicles feature extensive high-voltage networks that carry hundreds of volts between various electrical equipment. To ensure operational safety, safe measurement solutions are required for high DC and AC voltages as well as all relevant physical parameters, from temperature and acceleration to force and pressure.

German specialist cable manufacturer SAB Bröckskes has been developing and producing high-voltage (HV) cables for electric mobility for about a decade. The company portfolio includes dedicated measurement cables for temperature, voltage, acceleration and strain gauges. It also includes single- and multi-channel type-K HV sensors, HV Pt100/Pt1000 sensors and HV test adapters.

SAB Bröckskes and its technology partner CSM have introduced a measuring system for high-voltage e-mobility components. The system, consisting of sensor cable, plug, socket and measuring module, enables the use of uninsulated sensors up to 1,000 V DC operating voltage. It is safety-attested according to DIN EN 61010 and designed for mobile use in electric and hybrid vehicles as well as stationary installations to measure current, voltage and power directly in high-voltage lines. The equipment is equally suitable for measurements on electrified municipal vehicles as well as on mobile forestry, agricultural and construction machinery.

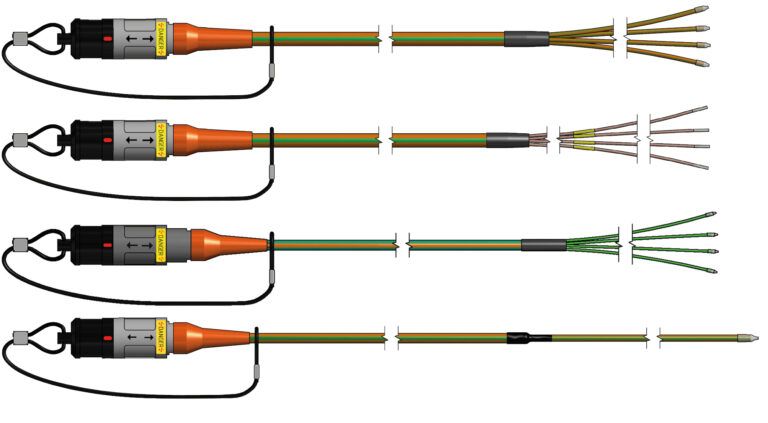

SAB Bröckskes high-voltage (HV) sensor cables, such as HV two-channel analogue measuring cables (90V), HV four-channel voltage measurement cables (90V) and four-channel voltage measurement cables (1,000V), ensure a reliable measurement chain from sensor to data acquisition. These also enable common low-voltage sensors to be integrated into HV applications. CSM has cooperated with the German automotive electronics specialist Vector Informatik to develop a scalable e-mobility measurement system for vehicles and test benches that enables data logging and measured value management in high-voltage and low-voltage environments. The decentralized measuring system enables, among other things, synchronous acquisition of measured data from measurement modules, vehicle buses and control units, direct measurement of current and voltage in high-voltage lines with up to 1MHz as well as multi-channel real-time power analysis.

A multi-level safety concept in accordance with the provisions of DIN EN 61010 for electrical measuring, control and laboratory equipment ensures safe high-voltage (HV) measurement. An isolation barrier in the measurement module ensures secure transmission of measured data and safe power supply. All SAB sensor cables feature multi-layered insulation to protect against electric shock. A blue intermediate insulation, which acts as a wear indicator, signals damage to the cable sheath. The especially developed HV connector for the sensor cable is plugged into the HV module socket through a kink-protection sleeve. The HV plug and HV sockets are designed to be touch-proof. Before shipping, each individual measuring module undergoes testing in accordance with DIN EN 61010, which is documented in a test report. An accredited test laboratory carries out type tests of the entire system consisting of measurement modules and signal cables. In addition, the units are tested for EMC, shock and vibration resistance as well as their degree of protection of IP65 or IP67.