Data acquisition instruments gather accurate and synchronized data for comprehensive testing, analysis and optimization of HEV/EVs

Testing of hybrid-electric and electric vehicles demands not only high bandwidth voltage and current measurement capabilities but also high dynamic range and accuracy. Data acquisition (DAQ) systems have become faster to handle the high bandwidth required to evaluate today’s electromotors and inverters. Engineers use instruments such as the Sirius XHS from Dewesoft to measure and analyze the performance of motors, including electrical power, mechanical power, efficiency, and thermal characteristics. The Sirius XHS has a sample rate of 15MS/s and a bandwidth of 5MHz, which enables it to capture high-frequency voltage and current signals with precision. This enables engineers to evaluate performance and optimize powertrain components. In addition, patented SuperCounter inputs with advanced input filtering allow torque and RPM sensors to be connected. Captured data can be transferred to any host using the open OPC UA industry-standard protocol. In addition, the data is available over XCP or CAN protocols for easy connection to ECU calibration software packages.

But it’s not just the recording instruments that have been improved – sensors have seen major advancements as well. For example, Dewesoft’s new DC-CT current transducer represents the latest in high bandwidth and high accuracy current transducer technology. Its patented Platiše closed-loop technology continuously measures residual magnetic flux in the core resulting from the difference between the primary and secondary (compensation) currents. It combines all the benefits of a zero-flux current transducer but with far less power consumption. Lower power consumption allows for a smaller form factor, permitting engineers to install the DC-CT where other sensors won’t fit.

The DC-CT current transducer handles a wide range of motor, inverter, and charging station applications, including measuring quiescent DC currents in idle mode, battery testing, electro-motor testing, and more. Its high bandwidth means it can be used to analyze higher harmonics of PWM switching frequencies up to 750 kHz. Combined with a Sirius XHS DAQ instrument, the DC-CT is used for motor and inverter analysis, charging station analysis in both DC and AC applications, and for driving cycle testing like WLTP (Worldwide Harmonised Light Vehicle Test Procedure) for range determination of BEV, HEV, FCEV, and PHEV vehicles.

For measuring high voltage and current at the same time, Dewesoft has released two new versions of the Sirius XHS-PWR. This device combines Dewesoft’s DC-CT current transducer with a ±2,000V input. XHS-PWR is available in two versions: one that measures current up to ±500A (short term), and one with ±2,000A capability. Both versions feature a 15MS/s maximum sample rate. These instruments comply with the EN 61010-1 safety standard, ensuring channel-to-channel and channel-to-ground isolation up to CATII 1000 V. Their IP65-rated chassis, which completely encloses the power lines for safety, operates reliably between -20°C and 70°C, and withstands high shock and vibration levels. It also includes internal temperature monitoring.

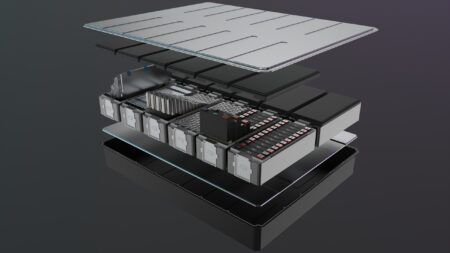

Dewesoft data acquisition instruments provide the capability to gather accurate and synchronized data from multiple sensors, enabling comprehensive testing, analysis and optimization of HEV/EVs through every stage of development and performance assessment.