Ulrik Grape, CEO of NAWA Technologies, discusses a hybrid battery that could slash pack weight by almost a third

There’s no doubt that automotive battery systems are improving dramatically, but what if you could combine two different types of technology, giving you the best mix of energy storage and power?

That’s the theory behind the hybrid battery – a combination of lithium-ion and ultracapacitor – and it could dramatically slash pack weight, boost overall efficiency, and improve the system’s lifetime.

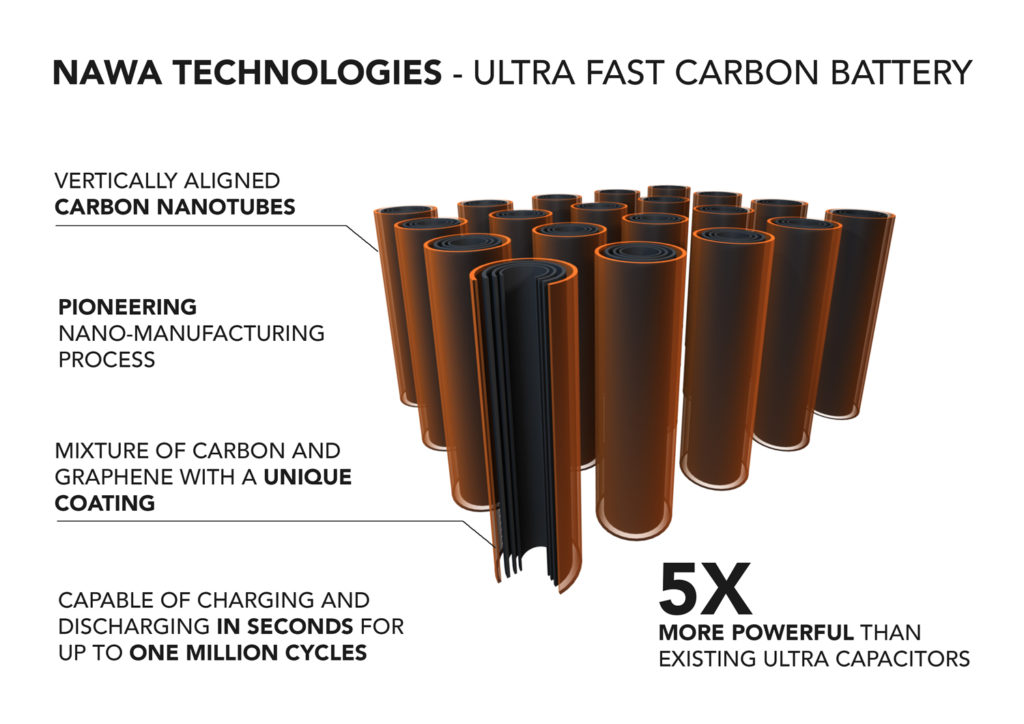

At NAWA Technologies, we’ve developed a new type of ultracapacitor based around a combination of vertically aligned carbon nanotubes. Capable of charging within seconds (and doing so over one million cycles), this technology can offer between three and five times the power and energy capability of existing ultracapacitors.

Called the Ultra Fast Carbon Battery, it bridges the gap between existing ultracapacitors and lithium-ion cells. However, ultracapacitors – even the most innovative one – still can’t compete with lithium-ion batteries on energy storage. You could certainly power a small car with ultracapacitors, but its range would be short and it would need to be charged frequently. This would make for an ideal city car or shared car, but for the broader automotive industry, we see the full potential of our technology being unlocked by a hybrid battery system.

Let’s look at how energy is recovered and used within an electric car. During regenerative braking, only around 20-30% of the energy is recouped by a conventional lithium-ion battery because its chemistry means it just can’t accept the high charge rate without jeopardizing safety or its lifetime. However, because of their ability to charge and discharge in seconds with no losses in performance, our ultracapacitors can recover around 90% of that energy.

Let’s look at how energy is recovered and used within an electric car. During regenerative braking, only around 20-30% of the energy is recouped by a conventional lithium-ion battery because its chemistry means it just can’t accept the high charge rate without jeopardizing safety or its lifetime. However, because of their ability to charge and discharge in seconds with no losses in performance, our ultracapacitors can recover around 90% of that energy.

In this way, they are ideal for taking heavy loads like regenerative braking, harnessing more energy more quickly than a lithium-ion battery. They are then very good at discharging this energy quickly, ideal for giving rapid bursts of acceleration. Again, far better than a lithium-ion battery could offer.

Put the two together and you can reduce the size of the lithium-ion battery as the ultracapacitor is taking away some of the former’s work load. In the short term that means less overall weight, more efficiency and better throttle response.

In the long term, because an ultracapacitor can be charged more than a million times – and it is taking the heavy loads – it is possible to give the lithium-ion battery just the gentle loads such as regular charging and discharging. This then prolongs the life of the lithium-ion battery and the whole energy system. So, over a lifetime, costs will be lower.

Let’s put some more numbers to this. When we say the hybrid system would be far more efficient, by how much could we slash pack weight? Well, we carried out some digital simulations on one of the world’s most advanced automotive batteries: the motorsport battery used in Formula E, which is a highly sophisticated lithium-ion system.

We discovered that by combining our ultracapacitors with this battery, we could reduce overall weight from 300kg to 210kg, with the same overall power, by making the lithium-ion battery smaller and reducing the complexity of the energy and thermal management system. That’s a 30% weight reduction, but with more performance and greater range because the overall pack weight is much lower, not to mention longer life for the system. You don’t need us to tell you how quickly any automotive engineer would jump at the chance to save nearly 100kg on any part of the vehicle’s architecture.

We could certainly foresee this hybrid battery system being translated to road cars, most likely on a high-end supercar initially, but it wouldn’t take too long before the technology could trickle down to an even wider market. We could easily see a hybrid battery system arriving in vehicles within the next four to five years. The great benefit would be when the car is doing a lot of braking and accelerating, and driving at moderate speeds – such as within an urban area, which is where 80-90% of the usage of an internal combustion engine car is today anyway.

What’s more, because our batteries are based on an abundant, accessible and natural material such as carbon they are recyclable, as well as potentially reducing our reliance on lithium. It really could be the best of both worlds.