Tony Austin, technical director at Rosti, explains how injection molding could offer the perfect solution for mass manufactured e-mobility applications.

A number of factors are driving the rapid development of e-mobility, not least government legislation and environmental pressures.

Moreover, with the global commercial electric vehicle market projected to grow at a compound annual growth rate of 39.85% – from 125,212 units in 2017 to 1,831,865 units by 2025 – e-mobility research and development is advancing at an unprecedented speed.

The internal combustion engine technology hitherto used to power vehicles is losing its foothold, with today’s OEMs engineering new platforms within the light-, medium- and heavy-duty e-mobility markets. These platforms are expected to achieve the same performance levels as their more traditional counterparts. Equally demanding, however, will be facilitating the leap from today’s low-volume prototype manufacturing featuring emerging technologies, to the mass production requirements of tomorrow.

Rosti is already active in the e-mobility/battery market and is working with some of the world’s leading OEMs to use proven production techniques to meet current manufacturing challenges head on. One such challenge involves the battery pack carriers used on e-mobility platforms. Battery technology is the key for making vehicles operate for longer and the not-so-humble battery carrier has a big role to play.

The role of the battery carrier

Looking under the hood of any conventional vehicle will reveal that the battery carrier is a relatively uncomplicated object. Usually manufactured from metal, its role has been to provide a platform for supporting the traditional lead-acid battery and offer some degree of protection in the event of impact. However, as e-mobility vehicles have continued

to evolve, the battery has become the lifeblood of the system.

Both vehicle reliability and range rely on the battery technology utilized, and so any threats to battery performance, such as hot climates, have to be countered. Essentially, an increase in ambient temperature results in reduced e-mobility battery life; the hotter the batteries, the faster chemical reactions will occur and the faster the battery will discharge. Independent tests have shown that the self-discharge rate of a battery doubles every time the temperature rises by 10°C (50°F). It is also imperative that batteries are protected from overheating, which is possibly the worst scenario, as it will lead to rapid damage.

The modern carrier

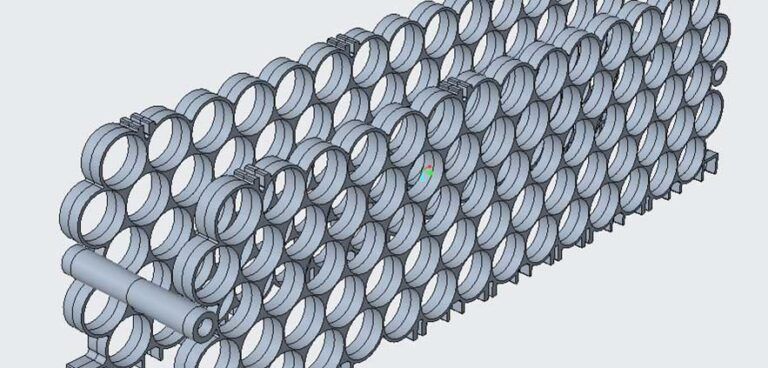

The modern battery carrier has become a vital element in the move toward effective thermal management, and e-mobility OEMs are looking at how they can keep multiple batteries cool to replace forced-air cooling. This has led to the implementation of a special channel structure within the carrier component that enables cooling fluid to be passed through or around the cells. What’s more, the channel structure permits transient cooling.

Rosti is working with OEM customers to offer packaged solutions in this area. The latest battery carrier designs are often highly complex, which means that producing a finished component through conventional manufacturing techniques such as CNC machining or pressing is not always achievable. It’s also important to note that 3D printing, which is seen as a future breakthrough technology, still has drawbacks in terms of the capital expenditure required. Nor can it meet the industry’s high-volume production demands. So, what is the alternative?

Injection molding for EV battery carriers

In the injection molding process, source material is melted and injected into a mold at high pressure. The part cools in the mold and is ejected, before the process begins again. But is injection molding the optimum manufacturing process to use for electric vehicle battery carriers? For years, Rosti has been challenged by many OEMs – across multiple markets – to design complex molds with numerous in-mold features, something that would almost certainly be required for battery carriers used in e-mobility applications. For example, Rosti can design the cooling channels to become an integral part of the molding. Utilizing in-house, state-of-the-art mold-flow simulation software, Rosti is able to take ideas from concept to reality, producing in one pass a part that contains all the features required of a modern battery carrier.

But again, is injection molding the right manufacturing process for battery carrier applications? Well, another way to look at this dilemma is to think about the potential volumes required. If e-mobility reaches its potential with regard to the number of units forecast, then manufacturing volumes are set to be very high indeed. This figure also needs to consider the vast amount of spare battery packs – and therefore carriers – that will be needed, not to mention power supplies required for other markets.

Rosti believes that neither CNC machining nor 3D printing will be able to cope with these high volumes, nor will these processes provide the target piece-part costs demanded by OEMs. Instead, a repeatable, cost-effective and fast process that offers structural rigidity is required. This is where injection molding offers significant advantages, not least the ability to scale production accordingly.

Sure enough, up-front cost for injection molding can sometimes be slightly higher due to the need for tooling, but the engineering benefits and economies of scale must be considered. Once the up-front cost has been amortized, the price per unit using injection molding is highly competitive. What’s more, the process is very repeatable – a good characteristic when trying to ensure brand consistency and part reliability in high-volume production. A further benefit is that injection molding can reduce the number of parts needed, as it offers the ability to integrate ancillary parts such as brackets. Such design freedom has obvious benefits to the bill of materials and production assembly times.

Does injection molding offer the right materials?

For this application, the key is to involve the raw material producer from day one of the project. For example, there is a huge need to reduce weight in battery carrier applications; it is not an option to reduce battery cell weight, so instead the carrier has to be lightened. Although injection-molded solutions offer a lighter alternative to traditional metal carriers, will these parts offer the strength needed to both support the battery and protect it from external factors? Rosti’s in-depth consultations with raw material manufacturers ensure that the right composition of material is deployed, one that can deliver all the requirements of thin yet strong wall construction. Furthermore, the specified material always meets the UL94 V-0 flammability resistance standard, thus delivering the confidence of in-application legislation compliance.

As the world moves toward an e-mobility future, mass manufacturing appears to be the next challenge. Rosti is convinced that injection molding has a role to play, and through close cooperation with OEMs, a technology from the 20th century may just offer a solution for the 21st.