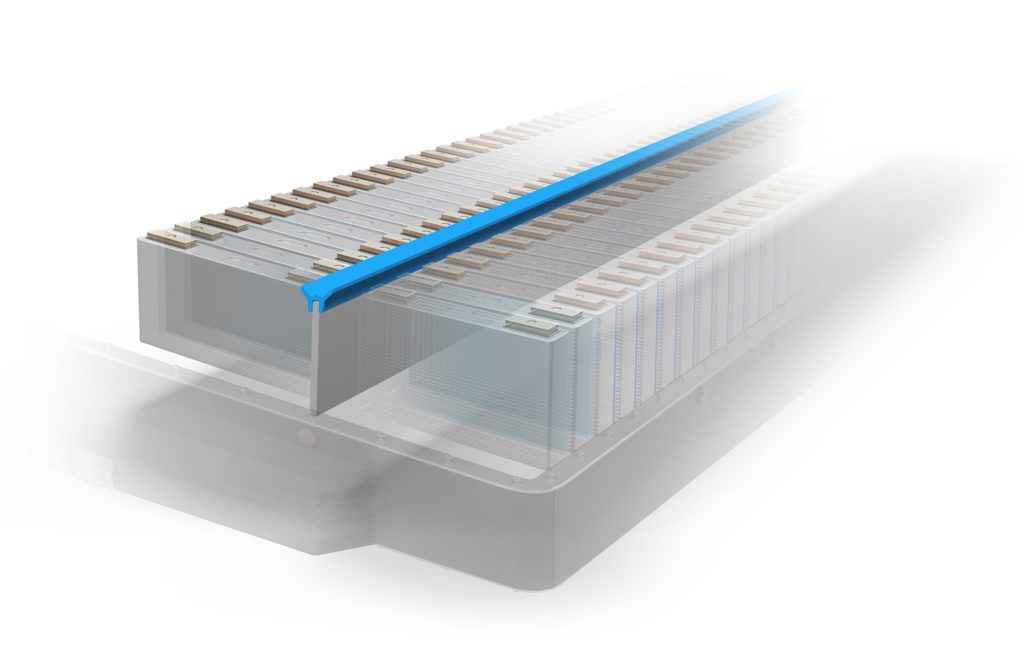

Tech company Freudenberg Sealing Technologies has developed 3D thermal barriers to help slow down the possibility of thermal runaway in higher energy density lithium-ion batteries. The 3D thermal barriers can be used at various positions within the battery and have already proven reliable in their initial series productions as a preventive measure, by increasing resistance to propagation.

With over 100 million electric cars expected to be on roads worldwide by 2030, many manufacturers are working on achieving higher ranges and shorter charging times, which is why high-performance batteries are a priority. But in lithium-ion batteries, higher energy density increases the risk of thermal runaway. For that technical environment, Freudenberg Sealing Technologies has developed thermal barriers to slow down or even stop thermal runaway.

“What is completely new is that the thermal barriers are now also available in customized, flexible 3D geometries, which makes it possible to use them in various positions within the battery and allows for integration of additional components,” said Andrew Espinoza, Global Vice President Technology of the Oil Seals Powertrain & Driveline Division at Freudenberg Sealing Technologies.

Beyond the existing two-dimensional barriers, such as flat mats and thermal blankets, the 3D variant offers customer-specific, three-dimensional geometries which can be produced in a variety of high and low volume manufacturing processes, such as, injection molding and continuous extrusion. Profile seals, module separators and covers, including those for bus bars, cooling lines or electrical components are a few of the products currently being produced. Another advantage: The manufactured, complex 3D geometries are lightweight and have minimal impact on the battery’s overall weight.

Specifically for these applications, materials experts at Freudenberg Sealing Technologies have developed heat-resistant, electrical, and thermal insulating materials. Testing of these materials has been completed in-house, proving that they can safely withstand temperatures of up to 1,200 °C. It is their special composition that makes these compounded polymers so extremely heat-resistant. It also makes them resistant against particle impacts, such as those that occur when cells are vented. The 3D thermal barriers utilize elastomer solutions, whether in solid form or as a foam, as well as plastic components such as Quantix Ultra®, which enables complex geometries.

With their 3D thermal barriers, Freudenberg Sealing Technologies has rolled out an innovative product that increases the safety of electric cars and lowers the risk of thermal propagation in future battery systems. As a partner of the automotive industry, Freudenberg merges market-specific know-how with unique expertise in materials, technology, and development, thus playing a leading role in the development of electromobility.