ThermHex Waben is a specialist producer of thermoplastic polypropylene honeycomb cores for lightweight sandwich panels and components. It has recently announced a new range of sustainable panels for lightweight applications including automotive, transport, wind and solar, logistics, B&C, and furniture.

Coming in a thicknesses of 6-20mm and densities from 1200 g/m² to 4200 g/m², the honeycomb panels are produced under the EconCore patented production process. The panels are increasingly replacing more traditional materials, such as plywood and thermoset panels, particularly in trucks, trailers and cargo boxes.

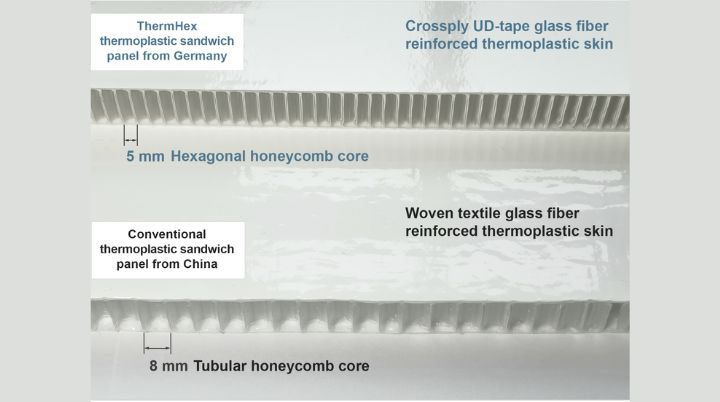

They are produced in a continuous in-line process by the extrusion of a polypropylene film, vacuum forming and folding. Allowing for direct and automated lamination of thermoplastic composite skins, this integrated process generates a honeycomb sandwich panel. Due to the smaller 5mm cell size of the honeycomb, ThermHex Waben says its cores deliver exceptional surface quality even with very thin skin layers.

It also notes the mechanical properties of high mechanical strength, resistance to chemicals and water as well as being lightweight makes it the material of choice within many composite markets including transportation, solar energy, marine, furniture, as well as automotive and more.

“Our polypropylene honeycomb cores offer cost savings and weight reductions while providing optimal mechanical performance for composite sandwich panels and parts,” said ThermHex Waben CEO Jochen Pflug. “Sustainable thermoplastic honeycombs have found their place within a variety of lightweight applications. We can now produce with equal high production speed and low production cost our honeycombs with a smaller cell size, leading to improved surface quality. They are also used for panels and parts with visible interior and exterior surfaces in cars and trucks.”