McLaren Applied has partnered with in-wheel motor specialists Elaphe to develop a powertrain that combines the British engineering and technology pioneer’s next-generation IPG5 800V silicon carbide inverter with the Slovenian company’s range of in-wheel motors. The joint electric drive will offer automakers significant space and weight savings, creating a highly efficient system.

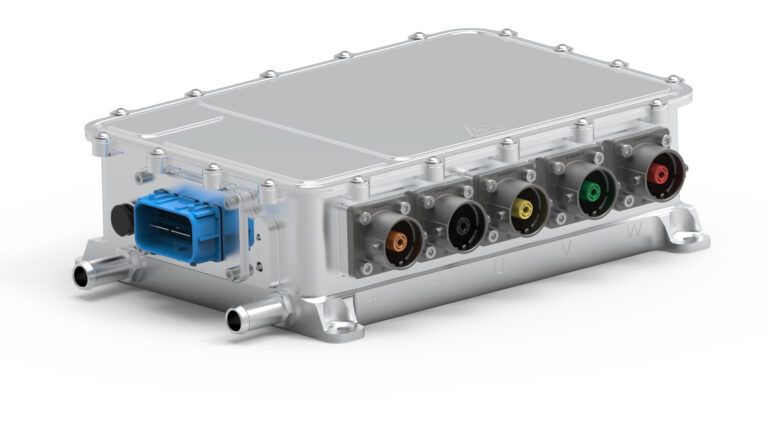

At just 3.79L in size and weighing 5.5 kilograms, IPG5 provides unrivalled power density, efficiency, and motor control. It’s highly controllable, offering variable switching frequencies and unparalleled motor response. Alongside Elaphe’s compact high-torque in-wheel motor, the compact, power-dense powertrain solution saves space and unlocks new possibilities for EV packaging.

The automotive team at McLaren Applied sees efficiency as leading what it describes as the next ‘wave’ of electrification. The first involved early pioneers of technology, the second, current wave is denoted by the breakthrough of EVs to the mainstream. The third stage is efficiency and will see inverter technology rapidly adopt silicon carbide (SiC) semiconductors, especially in 800V architectures and vehicles that need longer range where efficient power electronics are key. The fourth stage focuses on drivability and adding character back into the powertrains of electric vehicles, improving driver engagement and differentiation from the competition.

McLaren Applied believes high efficiency and superior driving dynamics will play an important part in the next wave of electrification. “Our IPG5 800V inverter enables customers to run different switching frequencies. And with variable switching frequencies comes the ability to run higher speed motors that are smaller and lighter,” said Stephen Lambert, Head of Electrification at McLaren Applied. “By combining IPG5 with Elaphe’s high speed in-wheel motors, we’re not only making the EV powertrain more responsive and efficient we’re making it more cost-effective too.”

“Elaphe is on a mission to make cars safer, more convenient and more exciting to drive,” said Dr. Gorazd Gotovac, CTO of Elaphe Propulsion Technologies. “This is why we are fully committed to removing all mechanical constraints and making the powertrain software defined. An efficient and highly responsive powertrain system is at the core of this, which is why McLaren Applied is the most natural partner and their IPG5 inverter is a perfect fit for our system.”