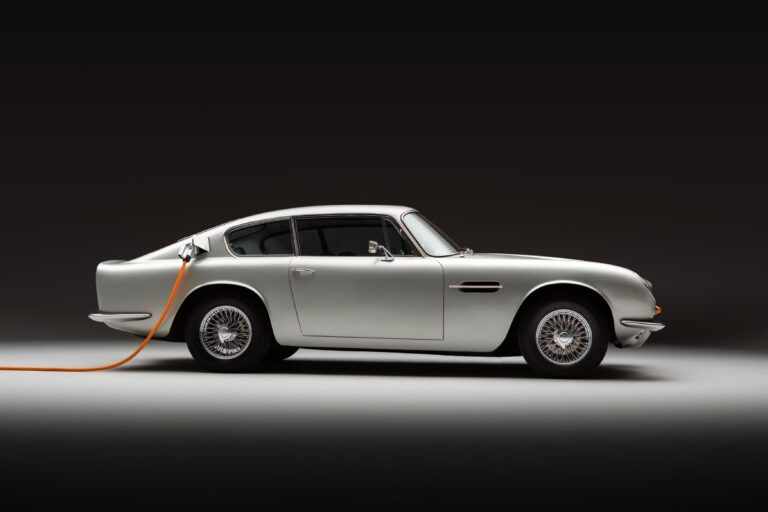

A specialist company that takes classic cars and re-engineers them to run on an electric powertrain has revealed its latest work, with an Aston Martin DB6 running purely on battery power.

British-based Lunaz was founded in 2018 and has launched the world’s first electric Bentley, as well as Rolls-Royce, Range Rover and Jaguar sportscars. Lunaz Design announces the completion of its family of the most celebrated cars in British history with the introduction of a limited production run of restored, re-engineered and electrified Aston Martin DB6 cars.

Lunaz takes extraordinary care in the selection of the marques it chooses to apply its restoration, re-engineering and electrification process to. Following the confirmation of orders for these first cars, Lunaz will now offer to clients across the globe a highly limited production allocation of Aston Martin DB6 cars in both Left Hand Drive and Right Hand Drive configuration. Exact prices will be communicated privately on application but exceeds $1million + local taxes. First deliveries are scheduled for the third quarter of 2023. Prices for rare DB4 and DB5 model cars will be available strictly on application.

This vision is executed by over 100 engineers, restoration specialists and craftspeople that work at Lunaz’ 62,000 sq/ft HQ on the Silverstone Technology Park. They are drawn from companies including Aston Martin, Bentley, F1, Ferrari, Jaguar, Land Rover, Mclaren and Rolls-Royce. As a collective they represent the largest technical team of their kind in the world engaged in the restoration, re-engineering and electrification of pinnacle classic cars.

The engineering process is led by Jon Hilton, Managing Director and Technical Lead. He blends experience at the pinnacle of motorsport, winning the 3 F1 World Championships with a career pioneering the use of alternative powertrains in mainstream automotive. He has gathered a team that includes senior technical minds that have led specialist engineering projects to customize heritage models for James Bond films. To deliver the ultimate electric driver’s expression of the DB6 he oversees a conversion process that represents re-engineering from the ground up.

It starts with an exhaustive inspection. Each corner is then weighed to understand the original weight distribution to the gram. This information informs decisions on chassis setup, powertrain packaging and suspension. The internal combustion engine and associated systems are then sensitively removed and stored on behalf of the client before the chassis is prepared for re-engineering and electrification.

The car is then 3D scanned; this allows the engineers to create detailed CAD models to ensure technical perfection in every step of the process. The electric powertrain has been engineered entirely in-house under Hilton’s technical leadership.

The company has developed a modular technical approach meaning the powertrain can be adapted to the exact requirements and characteristics of multiple marques and applications. Details of this are closely guarded but Lunaz stands alone in the classic car electrification space in deriving its cells, inverters and motors from European Tier 1 Suppliers. This counters an approach employed by many in adapting existing battery cells from crashed or disposed of passenger cars.

Luanz’ team of software engineers then programs its powertrain to create the ultimate driver’s Aston Martin . In the case of the Aston Martin DB6, the car will marry brisk initial acceleration with the requirements of a classic car that is very much built in the mode of a Grand Tourer. Indeed, the instant torque and silent delivery of an electric powertrain perfectly augments the intended use for long continental journeys with mixed road conditions.

Traditional coachbuilding and restoration skills are then employed and the car is stripped down to a bare metal shell. Even imperceptible body defects are addressed by hand before the surface finish process begins.