The Olli 2.0 is a driverless pod-like vehicle that incorporates groundbreaking technologies to deliver a solution to sustainable and accessible mobility.

Created by Local Motors, a digital manufacturer of mobility products, the first generation of the Olli was the world’s first 3D-printed car, as well as the first co-created, self-driving, electric vehicle. Now, the second version of the autonomous shuttle is stared production.

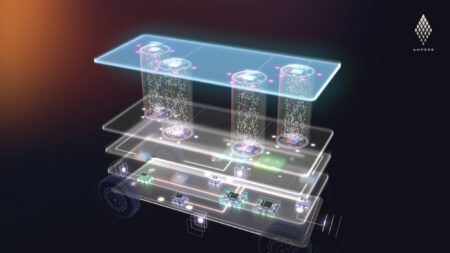

Its electric drivetrain is one of the key components to its success, with in-wheel motors from ProteanDrive providing quiet and efficient propulsion, while also enabling the shuttle to maximize interior space. Compared to conventional electrified powertrain formats, ProteanDrive offers greater powertrain efficiency, greater flexibility in vehicle design and allows solutions impossible to achieve with an e-axle. The highly integrated patented design includes all the core technology of an electric driveline within a single unit.

“Olli is spearheading one of the most exciting arenas for next-generation urban mobility,” says Ben Boycott, Chief Commercial Officer at Protean Electric. “In-wheel motors are the natural choice for autonomous vehicles.”

Protean Electric has been working with Local Motors since 2018, with the first Olli vehicle also using ProteanDrive IWMs. They have been working together to evaluate and integrate the ProteanDrive Pd18 in-wheel motor into Olli, which is currently deployed at 11 sites across the US, Europe and the Middle East. Customers include city administrations, universities, start-up mobility providers and public transit systems operators.

“We’re always focused on improving the technology and passenger experience within Olli and the selection of ProteanDrive in-wheel motors has helped us achieve a first-rate experience,” says Alex Fiechter, VP of research and development at Local Motors. “They are smooth and quiet. The flexibility afforded by an in-wheel drive with integrated electronics allows for our vehicle floor pan to be maximized for our users, not just for mounting and hiding hardware.”