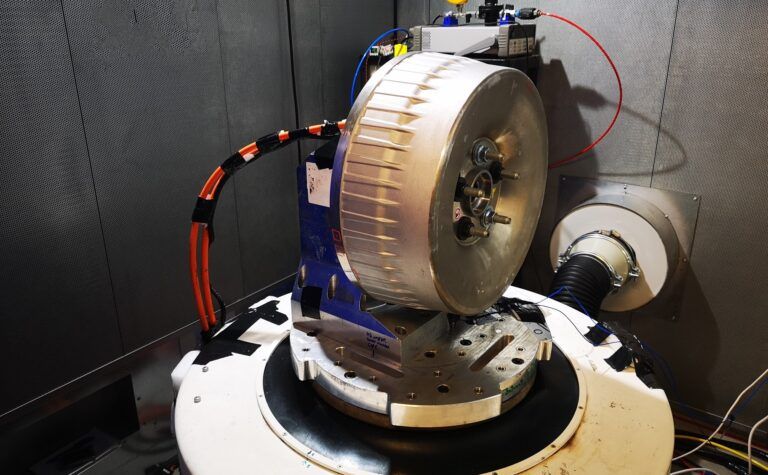

UK-based Protean Electric has completed validation of its new ProteanDrive Generation 5 (Gen 5) in-wheel motor (IWM). The Pd18 Gen5 model, designed for 18-inch wheels, has achieved a peak torque of 1500 Nm with an integrated inverter.

The validation program involved testing over 80 IWMs through 64 test programs, covering relevant legislation, regulations, and OEM standards. The motor is developed for mainstream automotive applications, meeting 15-year and 300,000 km durability requirements. It has been validated for environmental challenges such as wading, pothole impact, and other harsh wheel conditions.

Notably, the Pd18 Gen5 is designed and validated to ISO26262 as a Safety Element Out of Context, including mitigating ASIL-D hazards, which Protean claims is a first for IWMs.

“In-wheel motors are proving to be a pivotal, enabling technology for the next generation of EVs,” said Stephen Lambert, Chief Technology Officer of Protean Electric. “However, much like the first EVs, there needs to be a testing and validation rulebook set out. As an industry, much has been discussed about the design and validation challenges of in-wheel motors, particularly the demands of reliability and durability due to the harshest installation environments.”

The Gen 5 Pd18 is manufactured at Protean’s IATF 16949-certified facility in Tianjin, China. The company currently works with various OEMs and aftermarket applications.

The motor has been designed with a modular configuration, allowing for faster development of new product variations. Protean offers integrated and detached inverter options, with 400Vdc products currently available and 800Vdc products planned for release by the end of 2024.