It’s not only energy that is generated buy an e-motor, heat is a by-product too, and sometimes quite a lot of it. In demanding applications, excess heat in motor electronics can cause the power to be throttled or even shut down completely. Using a static solid cooling system can protect an electric motor from overheating without losing power, and this can be achieved by using a thermally conductive casting resin as a heat transfer medium.

Inventor Uwe Köhler began developing thermally conductive casting resins as far back as the 1990s and the result is Lambdapox, an innovative product from the start-up Lambda Resins. The company is a joint venture between the Köhler and the Nagel Group from Nürtingen, Germany, which has production lines for electric motor stators through its group company Gehring Technologies.

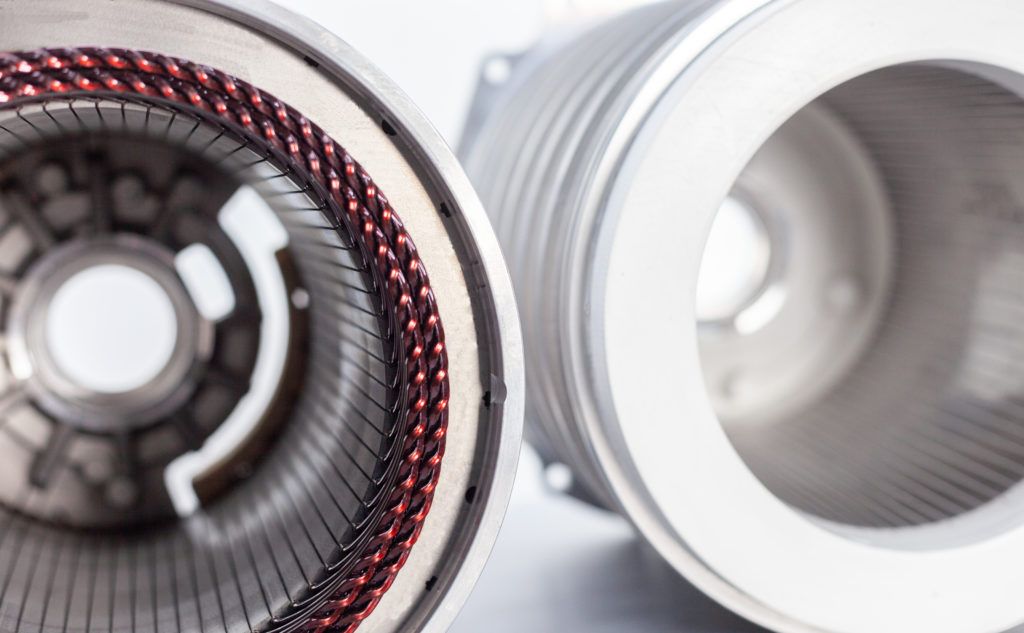

Lambdapox is a resin capable of thermally stabilizing e-motors and thus enabling continuous operations at a high level, reliably, effectively and without a great technical effort. To achieve this, the stator winding of the motor is cast with the resin in a vacuum process, resulting in the heat flowing into the surrounding cooling jacket much faster, negating the issue of heat build-up in the winding.

Lambdapox easily withstands the heat shock test from minus 40 to over 180°C. “Our casting resin causes a reduction in temperatures in the winding head,” says Köhler, “Depending on the configuration, the motors achieve up to 50% higher continuous power at the same thermal load.”

The cast resin is suitable for all high-performance motors, but especially EVs. The focus can be either to maximise performance, or to minimise space requirements while keeping performance unchanged. The former enables performance-enhanced variants of an existing engine without the need for a new development. The latter leads to a less expensive unit and a lower Co² footprint per kW of engine power. For EVs, lower engine heating results in higher efficiency, leading to increased range.