Engineers at technology company Continental have developed a new type of rotor sensor for electric motors. By utilizing inductive technology to detect the rotor position in a synchronous electric machine, the new e-motor Rotor Position Sensor (ERPs) promises more efficiency and smoother operations for EVs.

The ERPs was specially developed to control synchronous motors (where the rotor rotates at the same speed as the revolving field in the machine). To achieve maximum motor efficiency, the motor control unit needs to know the exact position of the rotor, making this type of sensor an essential part of synchronous motor applications. The ERPs is very flat and supports compact motor designs with a small overall length and is optimized to increase robustness to mechanical tolerances. State-of-the-art integrated circuits (ICs) are used for signal processing.

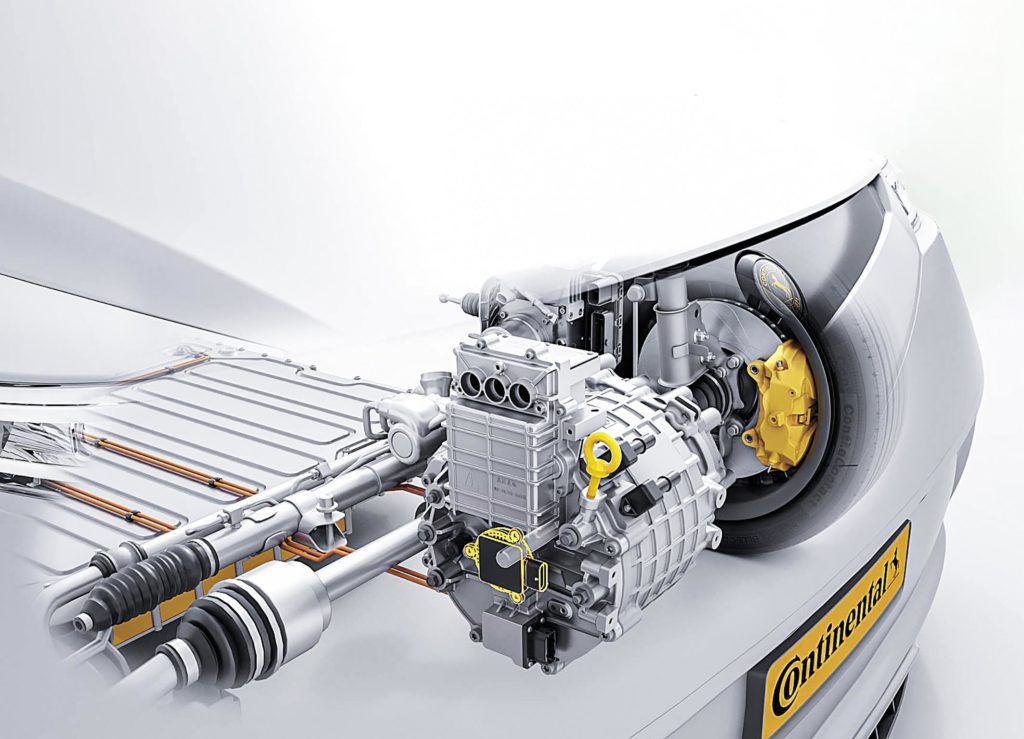

Continental’s comprehensive portfolio of sensors for EV engines and batteries are specifically designed to support road safety and electrification.

“The growth in vehicle electrification translates into more synchronous motors in the car,” said Laurent Fabre, head of the Passive Safety and Sensorics Segment at Continental. “This ranges from big and powerful ones like traction motors to smaller ones like electric pumps. Our standardized ERPs technology has a wide range of potential applications in electric vehicles. Measurement precision, compact dimensions and the all-in-one sensor concept combining several functions add to a high level of integration in the car.”