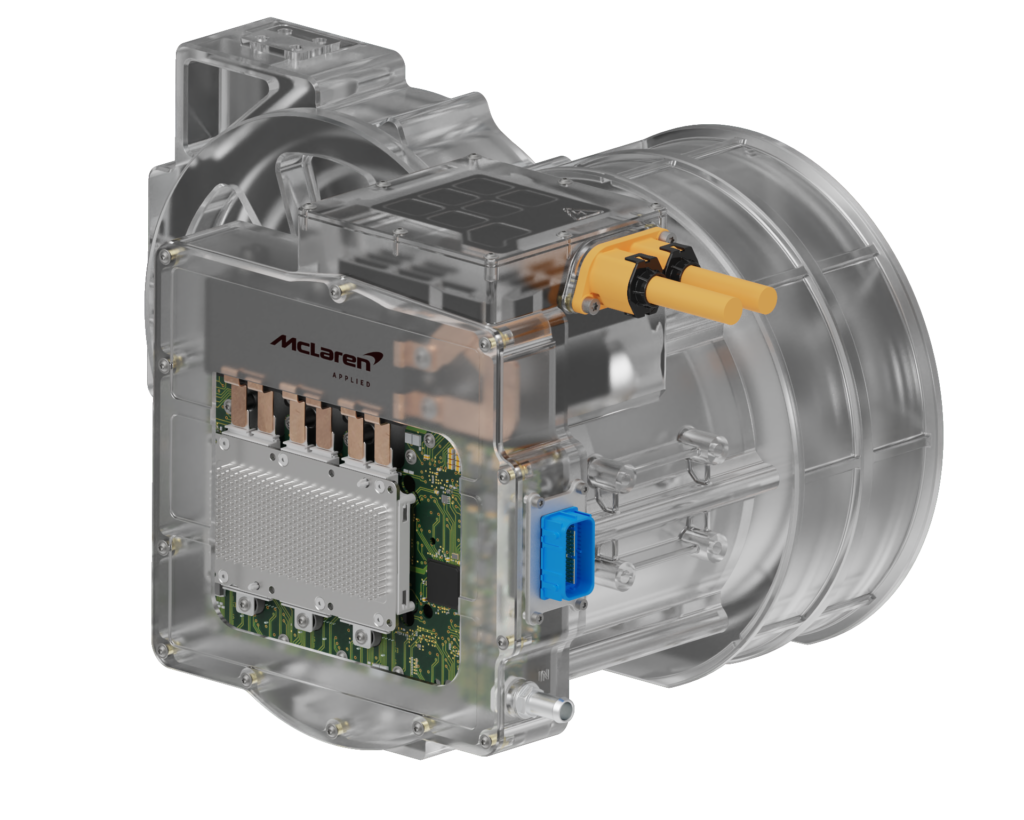

British engineering and technology pioneer McLaren Applied has launched IPG5-x, a highly flexible 800V Silicon Carbide (SiC) inverter that can be integrated into Electric Drive Units (EDUs). Targeting growing OEM demand for high-performing, integrated EDUs that save space and cost, the IPG5-x has been developed to work with a variety of motors and transmissions – especially in performance applications.

An adaptation of McLaren Applied’s current IPG5 800V SiC inverter, alongside the IPG5-x will coexist, the application of which will depend on customer need. The ‘x’ suffix was chosen because IPG5-x is a product designed for collaboration with partners looking to bring EDU products to market quickly and cost effectively. McLaren Applied is in discussions with several OEMs and Tier 1 suppliers and is working with transmission provider Tremec to jointly develop an integrated EDU for their first customer vehicle application.

“In our discussions with customers and partners, it’s become clear that OEMs are increasingly looking for the option to source integrated EDUs that save space, cost and speed up development time,” said Paolo Bargiacchi, Head of Product at McLaren Applied. “We’ve developed the IPG5-x to be highly flexible, so it’s ready to be integrated within any combination of motor and transmission. It carries over all our standalone IPG5’s qualities – peak efficiencies over 99%, continuously variable switching and fine motor control – building on the maturity of that product.”

Derived from decades of innovation in top tier automotive and motorsports, McLaren Applied’s IPG5-x offers best-in-class fine motor control and high efficiency through continuously variable switching frequencies; maximising the advantages of SiC semiconductors.

“The immediate focus must be on achieving greater drivetrain efficiency and cost reduction, which you can do through a product like IPG5-x,” said Bargiacchi. “The competitive landscape is ramping up significantly now that all manufacturers have established their product entry points.

“Models based on dedicated 800V SiC architectures are leading the way, driving a virtuous cycle: an efficient drivetrain inherently has a smaller battery, which makes the vehicle cheaper, lighter, and easier to control, and offers a smaller embedded and operating carbon footprint. It also increases range and speeds up charge times, building trust in the technology.”