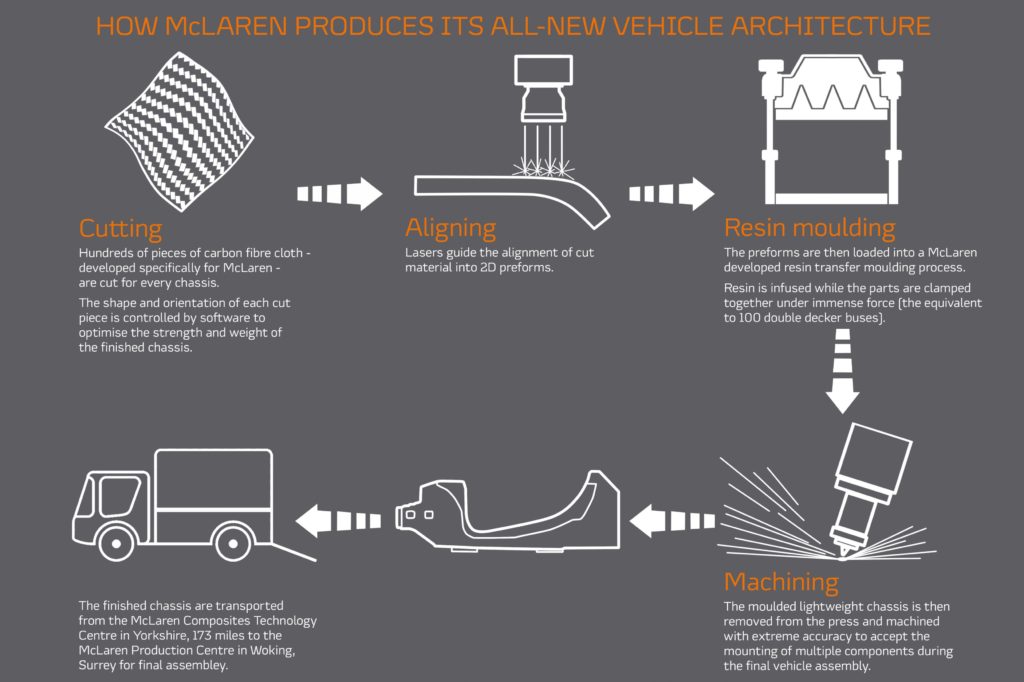

McLaren Automotive has confirmed the introduction of the brand’s all-new, flexible, lightweight vehicle architecture which will underpin its next generation of electrified supercars.

The new architecture, designed specifically to accommodate new hybrid powertrains, has been entirely engineered, developed and produced in-house in the UK at McLaren’s £50m state-of-the-art McLaren Composites Technology Centre (MCTC) in the Sheffield region.

The new flexible vehicle architecture utilizes innovative, world-first processes and techniques to strip out excess mass, reduce overall vehicle weight, while also further improving safety attributes.

It will underpin the next generation of McLaren hybrid models as the supercar company enters its second decade of series vehicle production.

The first new McLaren hybrid supercar to be based on the all-new architecture will launch in 2021.

“The new ground-breaking vehicle architecture is every bit as revolutionary as the MonoCell chassis we introduced with the company’s first car, the 12C, when we first embarked on making production vehicles a decade ago.

“This new, ultra-lightweight carbon fiber chassis boasts greater structural integrity and higher levels of quality than ever before with our new MCTC facility quickly becoming recognized as a global center of excellence in composite materials science and manufacturing,” said Mike Flewitt, chief executive officer, McLaren Automotive.

“Our advanced expertise in light weight composites processes and manufacturing combined with our experience in cutting-edge battery technology and high-performance hybrid propulsion systems means we are ideally placed to deliver to customers levels of electrified high-performance motoring that until now have simply been unattainable.”

The new architecture is said to enable McLaren to transition to 100% electrified supercars.

“For us, light-weighting and electrification go hand-in-hand to achieve better performance as well as more efficient vehicles,” Flewitt said.