A new inverter that comes complete with ASIL-D functional safety off-the-shelf has been launched to offer a cost-effective option for low volume runs of high-performance EVs, such as hypercars and one-offs specialty vehicles.

Developed by electrification specialist Equipmake, the HPI-450 addresses a major challenge faced by manufacturers of low volume production of electric sports cars from OEMs and start-ups alike by equipping their vehicle with an inverter that has ASIL-D functional safety and high-performance on budget.

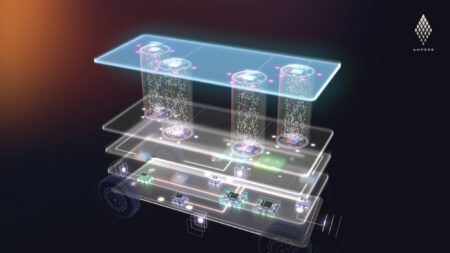

Playing a crucial role in the EV powertrain, the inverter converts DC charge from the battery to AC charge to drive the electric motor, also timing switching changes to adjust the frequency of the AC charge to control the speed of the motor, much like a fuel injection and ignition system does in a combustion engine.

Engineered and manufactured in the UK, Equipmake’s HPI-450 inverter boasts high power density of 30 kW/kg. Featuring Semikron IGBT modules, the HPI-450 inverter is capable of switching frequencies at up to 20 kHz.

Ian Foley, managing director of Equipmake said: “Until now, high performance inverters with ASIL-D functional safety have only really been available from Tier 1 suppliers to OEMs at considerable cost. That cost is not viable for low volume runs, so for a manufacturer of niche high performance electric vehicles – and even an OEM looking to do a low volume run of EVs – sourcing the right inverter has been a challenge. Equipmake has solved this with the HPI-450, which not only has off-the-shelf ASIL-D status but outstanding power density, at a cost that is very competitive even at low volumes.”

Based in Norfolk, UK, Equipmake provides EV technology to automotive OEMs and specialist supercar makers, producing everything from industry-leading electric motors to power electronic systems, all the way up to complete EV drivetrains, while also operating across marine, mining, off-highway, agriculture and aerospace.