As the vehicular electrification movement rapidly accelerates, the demand for electric drivetrains is increasing as a result, with one particular supplier GKN Automotive announcing it has seen sales of its products rise by 141% from 2019.

With electrified drivelines being introduced by nearly every OEM in hybrid and full-electric configurations, GKN is developing and testing its eDrive portfolio to keep up with demand and support a growing order book.

The company has a wide range of automotive driveline technologies and in July 2019, GKN produced its one millionth electrified driveline system and will be introducing six major OEM product launches in 2020. By 2025, the company expects to be producing one million eDrive units per year for global markets.

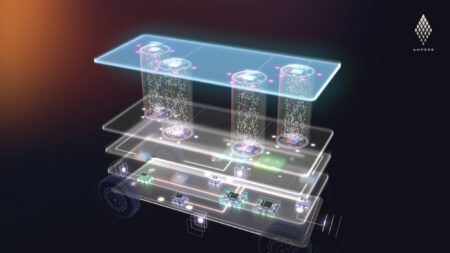

The next phase of GKN Automotive’s electrification strategy includes the development of the G400 eDrive System, currently undergoing testing in Arjeplog with a variety of inverter applications and eMotors developed in-house. This is in preparation for the forthcoming integration of Delta Electronics Inc. components into integrated 3-in-1 eDrive units.

Hannes Prenn, COO of GKN ePowertrain said: “The application of our G400 eDrive module into two very different vehicle platforms showcases how we are evolving and refining our scalable electric driveline technologies. As our eDrive order book continues to grow rapidly, we are accelerating the development of our standardized range of eDrive units to cater for all platform sizes and torque output requirements.

“To meet this demand, we have increased our inverter development capabilities by establishing a partnership with power electronics specialist Delta Electronics Inc. and have commissioned an in-house eMotor production line at our Bruneck facility in Italy. By integrating our inverter, transmission and eMotor technology into modular units, GKN Automotive is decreasing costs and reducing component packaging for automakers.”