The first micro-punch machine to be installed in the UK has been delivered to Driving the Electric Revolution Industrialisation Centre (DER-IC) North East to enable the manufacture of high-reliability high-power modules.

Inseto, a technical distributor of equipment and materials, has supplied the AMX P100 sinter press equipment to enhance the DER-IC’s power electronics, machines and drives (PEMD) capabilities.

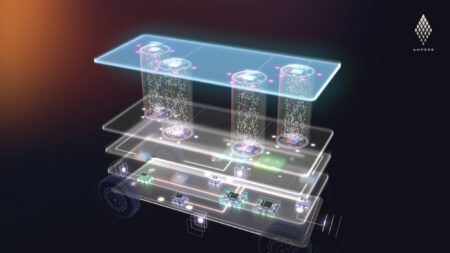

Sintering is a manufacturing process that combines pressure (mechanical force) and temperature to bond materials using a sinter paste. The process is increasingly required for the packaging of high-power semiconductor modules that incorporate silicon carbide (SiC) dies which, when channeling high currents, can produce heat at temperatures far higher than the melting point of solder (as traditionally used for conductive die-attach).

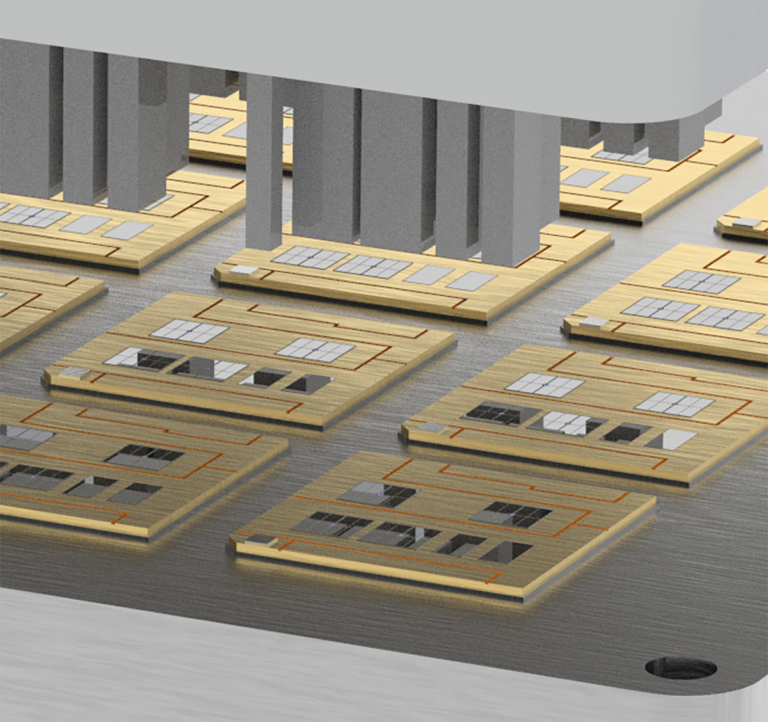

As for the AMX P100’s ‘micro-punch’ capability, this relates to how most sinter presses use a flat, single punch to apply force to the top of the dies. But if the dies are of different thicknesses, the same force cannot be applied across all. This means there is a risk of voids forming in the sinter paste beneath thinner dies – which in turn can result in failures in the field because of the high voltages and currents being switched. The AMX P100 can apply equal force to all dies, irrespective of their thickness.

Professor Derrick Holliday, Technical Director for DER-IC North East comments: “The drive by industry to create highly efficient, power dense and integrated power converters places increasing demands on power semiconductor switching devices. Manufacturers must be confident that products operating under these demanding conditions, particularly in safety-critical applications, are reliable. By ensuring the highest integrity bonds, this advanced sintering technology will facilitate the development of novel and advanced semiconductor packages and converter topologies, as well as supporting broader power switching device research, by both industry and academia.”

Inseto has also supplied DER-IC North East with two other pieces of equipment that will be used within the new facility for the manufacture of power modules and packs, as well as other components needed for PEMD

The first machine is a Kulicke & Soffa Asterion hybrid wedge bonder. Features include an expanded bond area, robust pattern recognition capabilities and extremely tight process controls. Together, these features deliver heightened productivity, bonding quality and reliability.

The second machine is an Amadyne FAB1 (flexible automatic die bonder). It is a modular micro assembly production platform designed for complex high mix and high-quality products. Features include short setup times (i.e. fast product changeovers, ideal for prototyping and process development) and remote system support / diagnostics.

Rachel Chambers, DER-IC North East Chief Operating Officer, comments: “It’s critical for us to ensure we provide best-in-class equipment and capabilities to support companies on developing, prototyping and scaling up their manufacturing processes. The sintering equipment in particular will give those using our facilities accesses to advanced manufacturing capabilities, and my team and I are looking forward to working closely with Inseto in helping all users meet their PEMD goals.”