As the electricity demand increases, so does the need to store electricity for a quick supply. The electricity is stored in batteries from renewable but variable energy sources, such as wind farms or solar panels, to support peak consumption or meet grid frequency regulation, or to operate electric vehicles.

The two most popular battery technologies currently are lead-acid batteries and lithium-ion batteries. Lead-acid batteries have a century-long history in commercial usage. They are reliable and highly recyclable. Lithium-ion batteries, on the other hand, have been developed for the past 20 years and they are applicable to portable solutions. The electrification of the automotive industry is underpinning the constant double-digit growth of lithium-ion battery market.

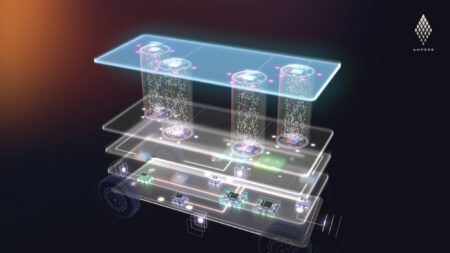

In lithium-ion batteries, Ahlstrom-Munksjö has been active for several years through its membership in the Soteria consortium. The Soteria consortium gives Ahlstrom-Munksjö access to the intellectual property for the Dreamweaver separator technology: a fiber-based separator thermally stable to improve the safety of lithium-ion batteries.

“Our development work, pre-industrialization trials and lithium-ion cell testing give us confidence that the intrinsic features of our material will contribute to the safety of the overall battery system and improve the separator’s processability in the manufacturing chain,” explained Bertrand Rupin, head of business development, energy storage.

Ahlstrom-Munksjö’s fiber-based separator demonstrates temperature stability and resistance at 200C and above, allowing more aggressive and faster drying conditions and the possibility to operate batteries at a higher temperature window beyond any temperature level achieved with current solutions. The separator also demonstrates a much better wettability than standard films, which allows faster filling of the cells and reduces the risk of delamination of the separator.

“We have built cells with our separator and run tests up to 500 cycles. The separator holds well in cells with cathodes: NMC622, NMC523 and NMC811, and this has given us strong confidence in the robustness of our solution up to 1Ah and 1C rate,” Rupin said.

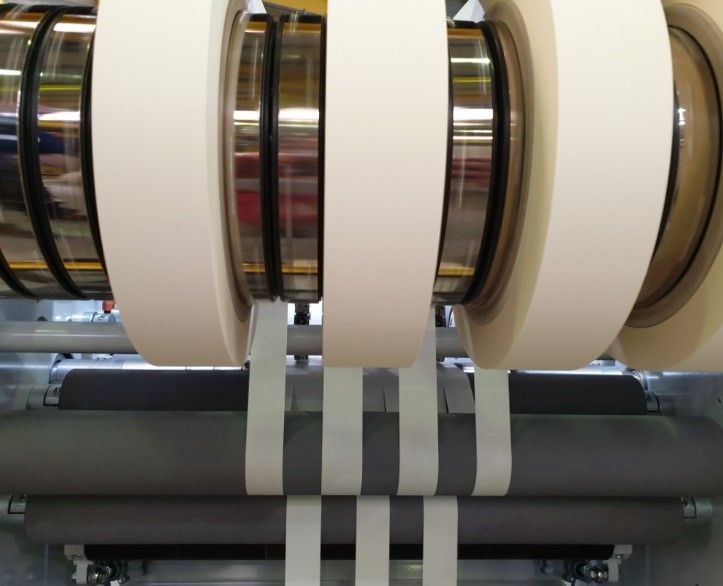

“This year, we have been expanding the promotion of Forticell LAB and investing in a state-of-the-art line, positioning us as a leading supplier of micro glass filter media and absorbent glass mat separators. At the same time, we have proceeded with the technical ramp-up and are exploring partnerships to – commercialize our fiber-based separator solutions to the lithium-ion battery industry.”