Contract electronics manufacturer BPC have invested in a Kulicke & Soffa (K&S) wire bonder to support its expansion into sectors where battery packs are required, particularly EV OEMs. Inseto – a leading technical distributor of equipment and materials – supplied and installed the Asterion EV at BPC’s base in Leicester. Renowned for its electronic design and PCB assembly services, BPC has the usual manufacturing equipment one would expect of a CEM; including pick and place machines, solder reflow lines and a vapour phase oven.

The company’s investment in the Asterion EV gives BPC additional assembly capabilities and including the ability to manufacture battery packs for EVs, other forms of e-mobility and the static storage of power (on the domestic and small industrial scale) from renewables such as wind and solar.

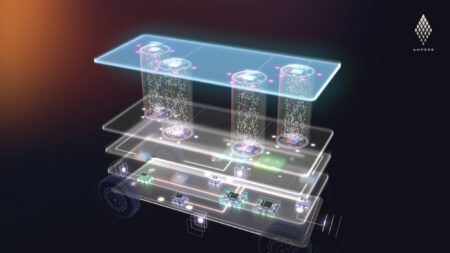

The EV is part of a family of Asterion wire bonders (the largest of which has a bondable area of 760 x 1440mm), the members of which are all ideal for establishing the numerous electrical connections found in battery packs. The EV has a bondable area of 300 x 860mm, pattern recognition capabilities and is driven by a direct-drive motion system that requires minimum maintenance, provides for extremely tight process control and delivers high repeatability.

“We’re already serving many sectors that use battery packs.,” said Mike Pitt, Sales Director of BPC Electronics. “We’re doing so by manufacturing circuit boards and cable harnesses, plus we do box builds. Offering battery pack design and manufacturing services is a logical expansion for us.”

BPC built a dedicated and spacious room for its Asterion EV, as the company envisages having a steady throughput of battery packs of varying shapes and sizes, and has already started building packs with 6, 12 and 24kWh capacities for several static energy storage applications. The company also plans to lease out time on its new wire bonder.

“We have ambitious expansion plans,” concluded Pitt. “These include purchasing additional wire bonders in the future, as all the indicators are that our domestic markets are keen to have battery packs and associated products, such as battery management systems, that are designed, built and can be supported by companies here in the UK. Despite government incentives, investing in e-mobility and energy storage still requires a leap of faith. We give customers peace of mind because we’re a UK- based OEM that can develop, manufacture and supply most of what’s needed.”