EIT InnoEnergy, one of Europe’s leading investors in sustainable energy and electric mobility innovations has announced a €4.2m investment in electric in-wheel-drive technology company, Elaphe Propulsion Technologies.

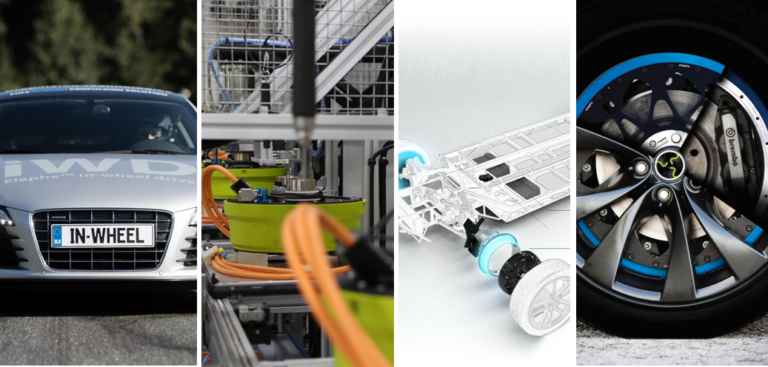

Elaphe is working on the current and future of mobility propulsion technology with its patented in-wheel powertrain system doing away with the traditional centralized architecture of a motor vehicle. This has resulted in the world’s first commercially scalable in-wheel motor system.

The advancements Elaphe’s approach provides do not lie in a specific product, or vehicle – instead they have developed a fully modular platform, combining the in-wheel powertrain with state-of-the-art software capable of optimizing each in-wheel motor in real time. As a result, Elaphe’s platform can be easily integrated into a wide range of vehicles, cutting down on manufacturing costs and removing the limitations of traditional centralized powertrains while increasing vehicle functionality and safety features.

“The partnership with EIT InnoEnergy strengthens Elaphe’s position both in the EU and globally. The provided investment and support will significantly accelerate commercial activities with automotive OEMs. This in turn will help us further optimize our best-in-class technology platform in accordance with customer requirements for production vehicles,” said Gorazd Lampic, CEO of Elaphe. “Therefore, being part of EIT InnoEnergy’s ecosystem gives us a competitive edge both from a technological as well as a business perspective and opens up exciting growth opportunities.”

With over 20 different in-wheel motors developed, integrated and tested in more than 50 fully electric and hybrid vehicles, Elaphe is the most experienced in-wheel motor propulsion solution provider on the market. Patented electromagnetic design enables specific torque up to 100 Nm/kg, 200 kW of power per regular car wheel, and superior packaging benefits. Elaphe is unique in that they offer OEMs the flexibility to integrate their preferred off-the-shelf corner components (brakes, rims, bearings, suspensions etc.) while also offering a turnkey solution.

By increasing the vehicle’s available space and reducing weight the move to in-wheel motors will allow for an unprecedented level of flexibility in terms of vehicle design, while also increasing efficiency by moving the torque to where it is actually needed. This will allow manufacturers to break from the traditional restraints of vehicle design, and build bold new products better suited for the mobility needs of a rapidly changing society. According to different market studies, the total addressable market for in-wheel powertrain by 2030 is predicted to climb from around 1.6 billion Euro in 2025 to around 12 billion Euro in 2030.

Several car manufacturers across the globe, from leading global brands to ambitious newcomers, are already working with Elaphe to apply their in-wheel technology to production vehicles. Those include US startup Lordstown Motors – an Ohio-based electric truck start-up who has recently purchased the Lordstown production complex from General Motors. Their Endurance pick-up truck has already accrued pre-orders in excess of 27.000 vehicles and is set to start deliveries in 2021.