Audi has commenced series production of electric motors at its plant in Győr, Hungary. The motors are produced across a floor space of 8,500m² according to a modular assembly production concept.

“Audi Hungaria has been involved in writing the growth story of the Four Rings for 25 years,” said Peter Kössler, board of management member for production and logistics at Audi.

“Our Hungarian subsidiary is now entering a completely new field of expertise with the production of electric motors. This exclusive know-how makes Győr into our main plant for electric motors and embodies our strategic transformation into a provider of sustainable mobility.”

“Audi Hungaria is taking on a pioneering role in the production of electric motors. I am proud of our employees’ high levels of expertise and motivation,” added Achim Heinfling, managing director of Audi Hungaria.

“They have successfully started the production of our new electric motor with great commitment.” The first electric motors from Audi Hungaria will be used in the Audi e-tron, the first all-electric Audi model, which will be built at the Audi plant in Brussels, Belgium.

“They have successfully started the production of our new electric motor with great commitment.” The first electric motors from Audi Hungaria will be used in the Audi e-tron, the first all-electric Audi model, which will be built at the Audi plant in Brussels, Belgium.

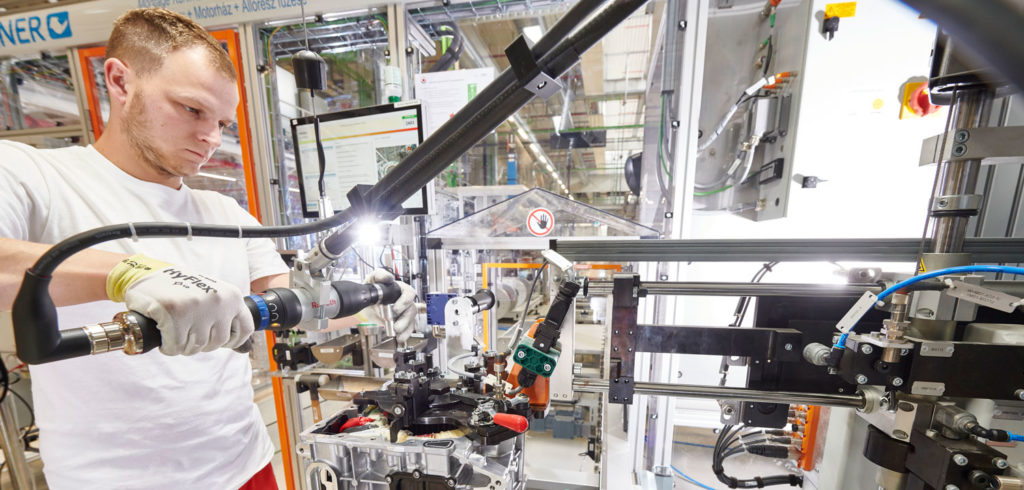

Ahead of the start of electric motor production, Audi Hungaria installed production equipment and islands within just one year. The departments for the development of electric motors and for production planning cooperated closely with the prototype manufacturing/production technology center in Győr to develop the required expertise.

The current production capacity is for approximately 400 electric axle motors each day and can be gradually increased. At present, about 100 people are employed in this new area, to be increased to more than 130 by the end of the year. Production is with one-shift operation, but will soon change to three shifts.

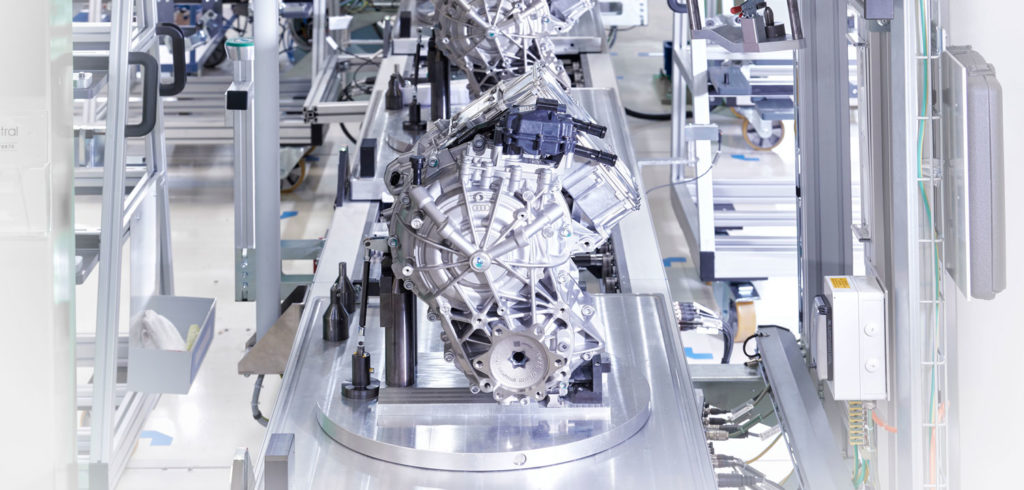

The electric motor from Győr offers a number of new features. With the stator – one of the core components of the motor – the aim is to insert as much of the thin enameled copper wire as possible into the casing: the tighter the winding, the more efficient the power delivery. A new winding and inserting center at Audi Hungaria makes it possible to wind the optimal amount of enameled copper wire particularly compactly and then insert it into the casing.

The electric motor from Győr offers a number of new features. With the stator – one of the core components of the motor – the aim is to insert as much of the thin enameled copper wire as possible into the casing: the tighter the winding, the more efficient the power delivery. A new winding and inserting center at Audi Hungaria makes it possible to wind the optimal amount of enameled copper wire particularly compactly and then insert it into the casing.

The electric axle consists of other large components such as the power electronics, which are located in their own housing, the gearing and two flange shafts that transmit the power to the wheels. The employees produce two electric-axle drive systems for each Audi e-tron, as both the front and rear axles are driven.

The production equipment, the robots and the bolting and measuring station are set out in fixed positions but are not linked together by a linear band. Instead, employees produce the drive systems according to a modular method in production islands. Despite a predefined assembly sequence, the modular system allows branched paths and more free scope in the production process. Driverless vehicles, controlled by an intelligent IT system, transport the parts to the workstations.

In parallel to the production facility, Audi Hungaria has installed three test benches for electric motors in the engine/motor development department, for testing and continuous load operation. Employees have undergone further training to become electrical experts in the production technology center for electric motors.