German automotive engineering firm FEV and battery developer ProLogium have unveiled a new Large-Footprint Lithium Ceramic Battery (LLCB) technology that promises significant advances in electric vehicle performance.

The battery features a silicon composite anode that delivers 10 times higher capacity density compared to traditional graphite anodes. According to the companies, this enables weight reductions of up to 300 kg or ranges of up to 1,000 km, depending on vehicle configuration. The solid-state electrolyte used in the battery is non-flammable and provides enhanced protection against thermal runaway and electrolyte leakage.

“For the LLCB solution, we have successfully combined ProLogium´s know-how in the field of cell development with our development, system and testing expertise,” said Dr. Thomas Hülshorst, Global Vice President Electric Powertrain at FEV. “Our collaboration on battery packs and concept designs focuses not only on regulatory standards, but also on market requirements. We even exceed these.”

The technology enables ultra-fast charging, reducing standard 30-minute charging times by over 80%. The battery can charge from 5% to 60% in five minutes, providing approximately 300 km of range. An additional three minutes brings the charge to 80%, adding another 100 km of range.

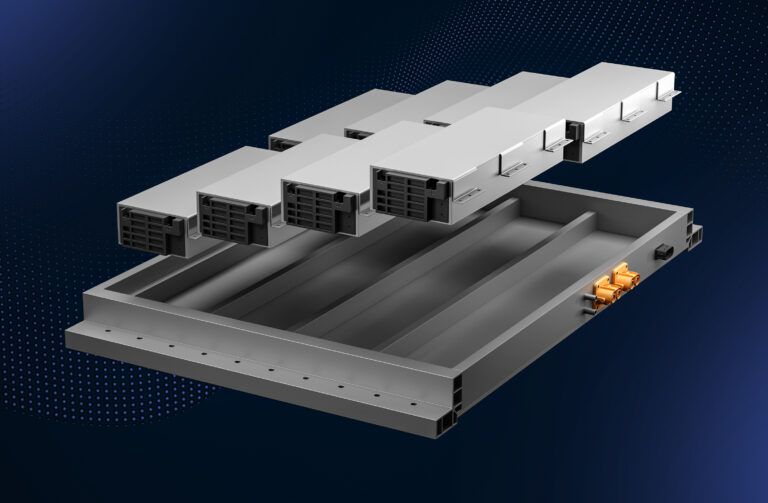

The battery’s slim cell design allows for more compact battery packs. “The modular design of the battery also makes maintenance much easier, saves costs and allows individual cells to be replaced and recycled,” Hülshorst noted.

The announcement was made at the Paris Motor Show 2024, where FEV and ProLogium confirmed their continued partnership on LLCB development. FEV, which employs 7,000 people across 40 global locations, provides engineering services to automotive manufacturers and has expanded into aerospace and energy sectors.