The new eDaily may share many features with its ICE-powered light commercial sister models, but, as Mike Cutts, Iveco UK light business line director explains, it has been re-engineered to take advantage of the all-electric powertrain. “The eDaily is linked to the previous diesel Daily, just electric,” says Cutts. “We’ve tried to bring a product to market that is as close to what the diesel van does but with an electric powertrain. We’ve taken that approach with the design of every aspect of the vehicle.”

The secret to the new van, chassis cab, crew cab, chassis cowl and minibus LCV family lies underneath the variety of body configurations. “The ladder frame chassis is exactly the same as the diesel vehicle, because the design and the shape of the chassis itself is ideal for the shift towards electrification,” says Cutts.

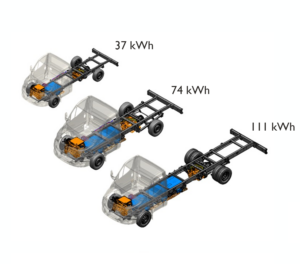

The batteries sit within the chassis structure itself with the option of one, two, or three packs depending on wheelbase length. This is determined by vehicle configuration and runs from 3.1 to 4.75m. This modular approach allows for increased flexibility over the number of batteries that can be specified, Cutts says, which in turn, allows for a more individualized product. “The three batteries are of a modular design, and they fit nicely into the gaps within the ladder frame. Because they are within the chassis structure, there is no increase in the height of the build platform for the actual chassis itself, which is important for body builders,” he says.

Iveco’s modular chassis approach allows for the addition or removal of batteries, or the swap of batteries between vehicles to balance out units which have been more heavily charged. Each battery is removed in an hour, with a replacement or additional unit fitted in the same timeframe. “We thought about how we can make it as easy as possible for that switch; the batteries drop out from underneath the chassis,” Cutts says. “This modularity allows for choice between range and payload.”

The battery packs weigh 270kg each, with an installed capacity of 37kWh. At 35kWh usable, the installed to usable energy ratio is 95%. Microvast supplies the pouch cells, building on a long relationship with Iveco Group. “Microvast also supplies battery cells to our HGV, bus, and coach divisions across Iveco Group and it is trusted and proven technology,” Cutts confirms. Designed to offer up to 2,500 full cycles, the HnCO-52Ah cells feature cathode nickel manganese cobalt patented technology, boosting energy density to 265 Wh/kg, with all necessary higher fire safety standards. Cells are assembled into packs by Iveco Group powertrain subsidiary FPT Industrial in Italy.

The battery packs weigh 270kg each, with an installed capacity of 37kWh. At 35kWh usable, the installed to usable energy ratio is 95%. Microvast supplies the pouch cells, building on a long relationship with Iveco Group. “Microvast also supplies battery cells to our HGV, bus, and coach divisions across Iveco Group and it is trusted and proven technology,” Cutts confirms. Designed to offer up to 2,500 full cycles, the HnCO-52Ah cells feature cathode nickel manganese cobalt patented technology, boosting energy density to 265 Wh/kg, with all necessary higher fire safety standards. Cells are assembled into packs by Iveco Group powertrain subsidiary FPT Industrial in Italy.

“The cell technology is one of the lightest on the market when it comes to usability and weight,” states Cutts. This helps with the LCV holy grail of payload. The 7.2-ton eDaily can carry up to 4.6 tons, while the eDaily van can carry up to 20m3 in volume. The two and three-battery models share the same 3.5-ton towing capacity as the diesel van.

No matter what the battery configuration, all versions of the new Iveco eDaily are powered by a permanent magnet assisted reluctance rear-central-mounted motor, with a continuous output of 90kW. When engaged in the ‘Hi-Power’ driving mode, output is boosted to 100kW (1 battery) or 140kW (2 and 3-battery) for two minutes. Power is sent to the rear wheels via a transfer box. Unique alternative rear axle ratios offer performance or efficiency, with up to 400Nm of torque available at 12,000rpm. “The focus is on delivering maximum efficiency to the rear axle,” says Cutts. Using the proven Daily axle technology – but optimized for each eDaily variant – peak axle efficiency of 97% is comparable to more traditional e-axle designs, with average efficiency of up to 92% on all GVW configurations.

“To achieve these efficiencies, our official partner Petronas has designed a new set of e-fluid products to assist with the operation of the transfer box, to give maximum efficiency from the motor,” adds Cutts. The tailor-made Iona Integra Plus solution has been specially formulated to reduce churning losses, and ensure system durability and oxidation properties, even at high temperatures.

Official WLTP combined cycle ranges vary from up to 74 miles (120km) for the single-wheel, single battery 37kWh, 3.5-ton model, through to 186 miles (300km) for the twin-wheel, three-battery 111kWh, 4.25-ton version. This distance increases to 248 miles (400km) on the WLTP urban cycle with a full payload onboard. A comprehensive all-weather testing program has seen vehicles evaluated in temperatures from -30°C to +50°C.

Official WLTP combined cycle ranges vary from up to 74 miles (120km) for the single-wheel, single battery 37kWh, 3.5-ton model, through to 186 miles (300km) for the twin-wheel, three-battery 111kWh, 4.25-ton version. This distance increases to 248 miles (400km) on the WLTP urban cycle with a full payload onboard. A comprehensive all-weather testing program has seen vehicles evaluated in temperatures from -30°C to +50°C.

One essential feature again takes its lead from the diesel version of the Daily. “The Hi-Power function is like a temporary turbo boost,” says Cutts. “If there is a heavy payload and the vehicle is on rough ground or a steep hill, or even towing, a temporary reservoir of energy can be used,” explains Cutts. This is ring fenced in the vehicle powertrain and accessed by depressing the accelerator pedal past its ‘finish’ position. Once depleted, it cannot be used again until it has refilled. AI learning technology is used to determine the available level of reservoir Hi-Power energy.

Electric power take-off (ePTO) technology of up to 15kW is supported to power refrigeration and other superstructures, and because this is independent of the traction motor, it can be used if the e-motor is turned off. Three driving modes and the same number of regenerative braking settings help feed energy back into the batteries. An 11kW on-board charger is standard, with 80kW DC rapid charging adding around 62 miles of range in 30 minutes.

As part of Iveco Group’s multi-fuel approach (see panel) a hydrogen fuel cell eDaily is set to enter small series production. The eDaily FCEV uses a 90kW (122hp) Hyundai-sourced fuel cell system, mated to the same 140kW electric motor and 37kWh battery as the regular eDaily. “The ladder frame chassis has also been designed to build hydrogen tanks into the vehicle and we’re giving even more future proofing than what’s coming in the next three or four years,” Cutts says. Up to 12kg of hydrogen can be stored onboard in 6 tanks, for a range of up to 218 miles (350km), and this adaptability means the commercial could begin life as an EV and then become an FCEV later.

The new eDaily fires the starting gun on Iveco’s multi-fuel approach to the commercial vehicle market. The company is developing battery-electric and hydrogen fuel cell heavy-duty (Class 8) trucks for Europe, with an e-axle designed and co-produced by FPT Industrial. Due to arrive in Q4 2023, the Iveco HD BEV has 738kWh of usable battery capacity from 9 Proterra-supplied batteries and a driving range of around 310 miles (500km). The Iveco HD FCEV uses Bosch fuel cell technology, and like the HD BEV, is based on Iveco’s successful S-Way heavy truck platform. The HD FCEV stores up to 70kg of hydrogen at 700-bar pressure, enabling a driving range of up to 500 miles (800km).

A new hydrogen-powered version of Iveco’s battery-electric E-Way bus has also been revealed. The E-Way H2 uses a fuel cell system supplied by Hyundai’s HTWO brand. The E-Way H2 has a 310kW (421hp) electric motor and 4 storage tanks that hold a combined 7.8kg of hydrogen. The FPT Industrial-supplied 69kWh battery pack can be charged by plugging into an electric vehicle chargepoint to give a potential driving range of up to 280 miles (450km).