Ionetic, a UK-based EV battery pack technology startup, has introduced Arc, a software-accelerated development system that aims to reduce battery pack development costs and production timelines for automotive manufacturers.

The system automates design processes and incorporates pre-validated components, potentially reducing the typical $30 million investment and four-year development cycle required for custom EV battery systems.

“As the push for electric vehicle adoption accelerates, OEMs need the right partners to bring competitive electrified vehicles to market as fast as possible,” said James Eaton, CEO and Co-Founder of IONETIC. “Our Arc system allows us to provide OEMs with pre-validated, tailored solutions – enabling them to remove inefficient development processes.”

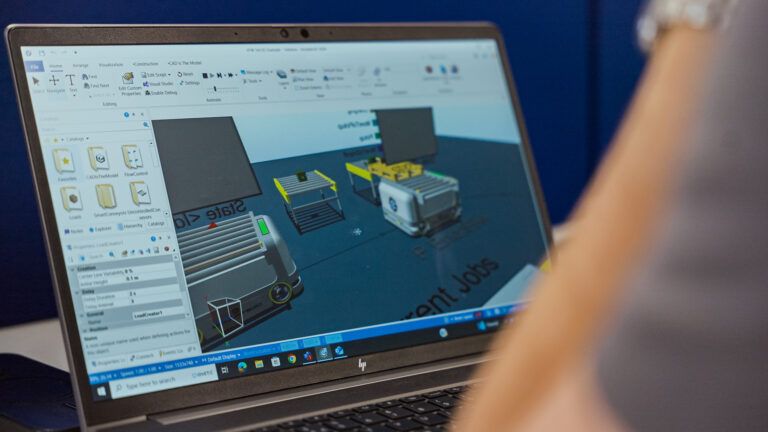

The Arc system combines AI-powered design tools, pre-validated hardware components, and flexible manufacturing capabilities. It targets manufacturers producing between 100 and 10,000 battery packs annually, particularly those developing trucks, buses, and sports cars.

According to Ionetic, 95% of global OEMs produce low-volume bespoke platforms. These manufacturers typically face a choice between expensive custom battery packs or lower-performance off-the-shelf solutions.

The system’s software uses AI to optimize and conceptualize battery pack designs, while its hardware framework supports multiple cell formats. The manufacturing approach follows a semiconductor fabrication model, allowing production lines to serve multiple customers without requiring significant retooling.

Founded in 2022, Ionetic developed Arc to address the time and cost challenges associated with bringing EVs to market.