Schaeffler has introduced a pair of drivetrain solutions for electric, hybrid and ICE vehicles – an integrated electromechanical actuator for multi-speed electric axles and an integrated parking lock actuator.

“With its transmission actuator portfolio, Schaeffler is playing an important role in making hybrid and electric vehicles fit for the future,” said Matthias Zink, CEO automotive at Schaeffler.

“By using our decades of expertise in the development of powertrains, we can optimally meet individual customer requirements and can develop energy-efficient and cost-effective solutions for all kinds of electrified powertrains.”

Schaeffler’s electric axle actuator (EAA) will go into volume production this year and is an example of how transmission actuators are used in hybrid and electric vehicles. The EAA is based on the proven active interlock transmission actuator with integrated interlocking, but operates without a selector axis.

Two adjustment motors are controlled only when gears must be engaged or disengaged. Except for a minimal idling current, this actuator has almost zero energy losses. Schaeffler not only provides the hardware but also develops the software to ensure optimum performance in the entire system.

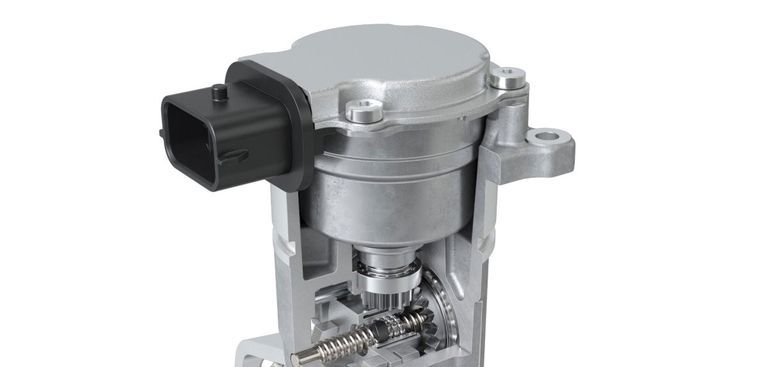

Schaeffler’s integrated parking lock actuator (PLA) was developed as an efficient actuation module for the parking lock function in electric vehicles. This actuator has a weight of less than 460g and requires very little installation space. This means that it can be integrated into electric axle systems or dedicated hybrid transmissions in an optimum manner. The reduced complexity of the parking lock’s mechanical system in the transmission also ensures above-average durability of more than 150,000 load cycles per unit.