Impact Clean Power Technology, a Polish company forming part of the Grenevia Group, has unveiled its plans for GigafactoryX, a 16,300m2 large-scale battery factory for electric vehicles and energy storage.

The project will be launched in the city of Pruszków, near Warsaw. Impact says this development will see a battery system weighing up to 500 kg for e-mobility and power generation created every 11 minutes.

Group project

Impact Clean Power Technologies’ business in the areas of battery systems, energy storage and electromobility is one of Grenevia Group’s four main business segments.

The construction of GigafactoryX will increase Impact’s production capacity to 1.2 GWh in 2024, and more than 4 GWh per year in 2027.

The factory will be fully automated, with facilities including a battery testing facility and an advanced research and development center.

The plant will also produce energy storage systems designed for the commercial power industry, including for large-scale electricity storage.

The battery systems will be based on lithium-ion cells in technologies: LTO (lithium titanate), LFP (iron-phosphorus) batteries and NMC (nickel-manganese) batteries.

Leading the charge

The creation of GigafactoryX means that Poland will be Europe’s leading supplier of batteries for the e-mobility industry, all based on Polish solutions” commented Bartek Kras, CEO of Impact.

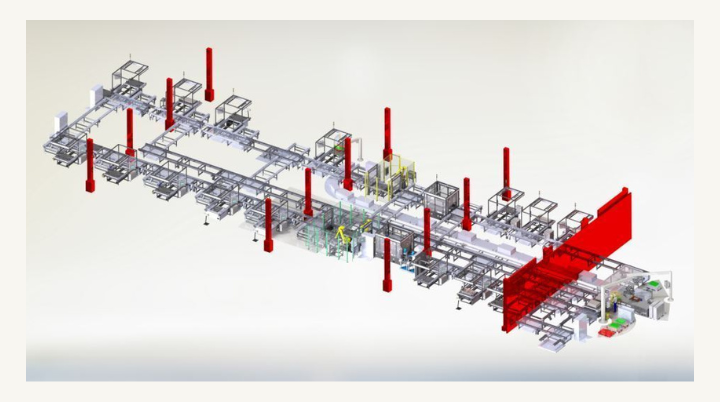

The company teamtechnik Production Technology Poland is responsible for the supply and installation of the production line that produces batteries for public transportation at GigafactoryX.

It is a TDJ-owned company specializing in building automated assembly lines for the e-mobility, industrial goods and life science industries.

The technologically advanced, safe production line will be dedicated to the production of battery systems for electric buses in three references, with the possibility of expanding by more.

“It is extremely important to us that the new plant has been designed in accordance with the principles of sustainable development,” added Kras; GigafactoryX, will be partially powered by photovoltaic panel, and an energy storage facility for about 1 MWh is also planned.

Production and automation

The first phase line has dimensions of 58x19m. Fourteen engineers worked continuously for four months on its mechanical, electrical and automation design.

The flexibility of the line is influenced by the use of a production loop, which allows production to be optimized depending on the type of product being produced. As a result, it guarantees savings in both space and costs for the investor.

The teamtechnik solution is also a key element for increasing Impact’s production efficiency. In 2024, the line will enable the production of 16,000 units of battery systems, compared to the current capacity of about 2,500 units.

It also guarantees reproducible product quality, as it includes full automation of processes such as robotic assembly of individual components, batching, screwing, vision inspection and a range of tests.

It will use Bosch Rexroth’s TS7 conveyor system for the first time in the world. Assembly work is scheduled to begin in July 2023.

Industry 4.0

The batteries for heavy duty e-mobility that will be made at the new plant owned by Impact will be a large-size product, with maximum dimensions of 1400mm x 1000mm x 400mm, and weighing up to 500 kg.

The design of the line will be based on technologies from the Industry 4.0 area, and includes the use of full traceability, NOK and re-Work policies.

Their production will be based on full product traceability, product management policies in case of non-conformities and their correction or repair.

The use of such solutions makes it possible to repair a non-conforming product already on the production line and run it through functionality tests again to get a result that confirms the expected quality.

The factory will be certified to IATF 16949:2016, ISO 45001:2018 and ISO 14001.:2015, ISO 9001:2015, as well as have the 6S system, which addresses workplace maintenance standards.

The commissioning of the first automated production line is scheduled for January 2024.