The world’s first electric fire truck has commenced production with Volvo Penta producing bespoke electric drivelines for fire service vehicle manufacturer Rosenbauer.

Named Revolutionary Technology (RT) it is built using adapted technology from Volvo Trucks and Volvo Buses, enabling Volvo Penta and its customer Rosenbauer to introduce a completely new vehicle architecture.

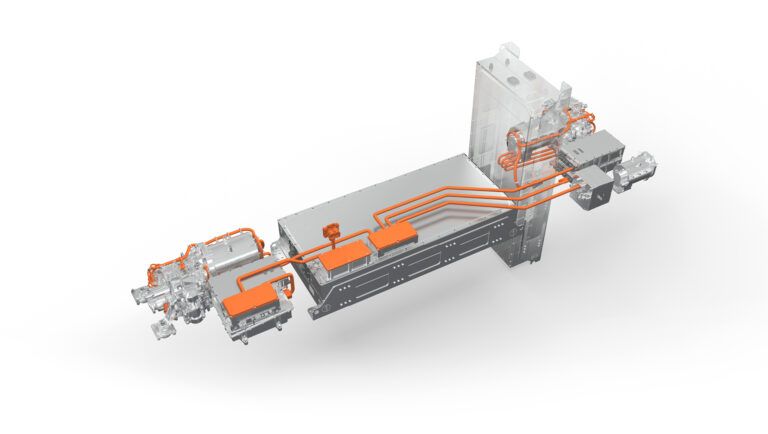

Unlike typical electric trucks, the RT requires added power with four electric drivelines to be able to run simultaneously – two for propulsion, one for the range extender to provide extra battery power, and one for electric power takeoff. To achieve this, the Volvo Penta engineers created a system that is completely cutting edge in terms of Volvo Group technology.

Due to the required compact dimensions of a city fire truck, Volvo Penta created a new Active Cooling Unit (ACU). This component was developed in part collaboration with Rosenbauer. The new ACU draws on a 600V system – instead of the conventional 24V – this extra power allows Volvo Penta to not only cool the batteries but also offer cooling capacity to the Rosenbauer vehicle. This is one way Volvo Penta has optimized the design and adapted the complete electric driveline system for a specific vehicle, considering the exact application, usage, climate, and environment it will operate in.

“We announced our emob partnership with Rosenbauer in 2019, and we have gone from concept to start of production in record time,” says Giorgio Paris, President of Volvo Penta Industrial. “This is a milestone in our electrification journey. We see a growing demand for electric solutions in the market today and – through collaboration and pilot projects, such as this one – we aim to meet this demand and the expectations of the future.”

Three Rosenbauer test firetrucks – powered by Volvo Penta electric drivelines – have already successfully been delivered to Berlin, Amsterdam, and Dubai. With fire crews able to experience the RT’s battery capacity and the many other advantages of not having a large diesel engine – such as increase crew cabin space and more side panel storage.

The first electric drivelines have entered the production stage at the Volvo Penta Vara plant in Sweden where the ACU is manufactured, and the system is kitted – loaded with software and packed together – to make installation as straightforward as possible for the customer.

“When it comes to developing new technologies, like electromobility, we see our customers as our biggest asset,” said Giorgio. “We have developed strong working relationships with our customers over many years, which is key in the transformation towards more sustainable and new technology solutions. By working closely on different applications and in an array of sectors we can develop solutions – in a stepwise approach.”