In an Australian first, Melbourne based company SEA Electric has commenced volume commercial production of the country’s first locally-built electric trucks.

“In Australia, carbon dioxide emissions from transport are now the second highest behind electricity generation, and are forecast to continue rising.

“Mass uptake of electric trucks in urban Australia has the potential to save up to millions of tonnes of CO2 each year, and provide up to 40,000 MWh of mobile battery storage, which is a potential future revenue stream.”

Two SEA Electric-badged vehicles, the SEA 300 and SEA 500, based on the Hino 500 Series and Hino 300 Series models, are now available for purchase.

“SEA Electric is privileged to be able to bring this Australian first to the marketplace,” said Glen Walker, SEA Electric regional director for Oceania.

“These trucks truly meet a need in the marketplace, and prior to this launch, we have received pre-orders for 46 vehicles from some of Australia’s biggest companies and councils.

“It represents an exciting phase in global EV development, and this places SEA Electric at the forefront.”

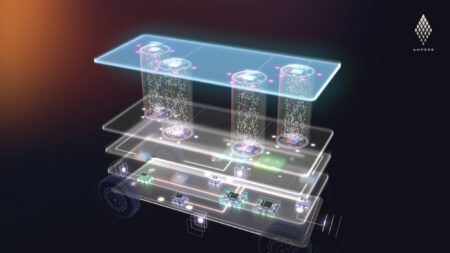

The trucks are propelled by SEA Electric’s SEA-Drive Power-System, which is available in various performance and range packages to suit applications from 4.5 tonne car license vehicles through to 22.5 tonne 3 axle trucks.

Previously only available as a retrofit option for existing diesel vehicles, the trucks are assembled from Semi Knocked Down (SKD) kits, complete with a fully integrated SEA-Drive Power-System from new.

Real world testing of in-service vehicles that travel up to 1000 kilometers per week has revealed daily recharging costs of less than A$14 per day using standard off-peak electricity prices of 15c per kWh.

Built on an upgradable architecture, the SEA-Drive Power-System can be charged using the world’s biggest charging network, which is 415V 3-phase power via the truck’s standard on-board charging equipment, with optional DC fast charging also available.

The fast charging option enables a charging rate four times faster than standard options, it is claimed. Another highlight of the trucks are the improved workplace health and safety conditions for operators, with the powertrain producing no noise or fumes while reducing vibrations, which combine to limit driver fatigue.

“Our electric Power System features a host of key features, including smooth application of torque, industry-leading range, whisper quiet operation, and importantly, a reduction in the truck’s carbon footprint, with zero emissions of carbon dioxide, nitrous oxide and methane,” said Walker.