UK hydrogen fuel cell innovator Bramble Energy has signed a memorandum of understanding (MoU) with independent engineering services provider the EDAG Group, to collaborate on the development of a digital integration of its patented printed circuit board fuel cell (PCBFC) into EDAG’s electric vehicle storage platform.

The digital investigation will involve the design of a customised fuel cell stack as well as the overall system layout fitting the EV platform (including batteries, hydrogen storage and FC stack with major Balance of Plant (BoP) components), with clear vehicle simulation data providing evidence for its feasibility.

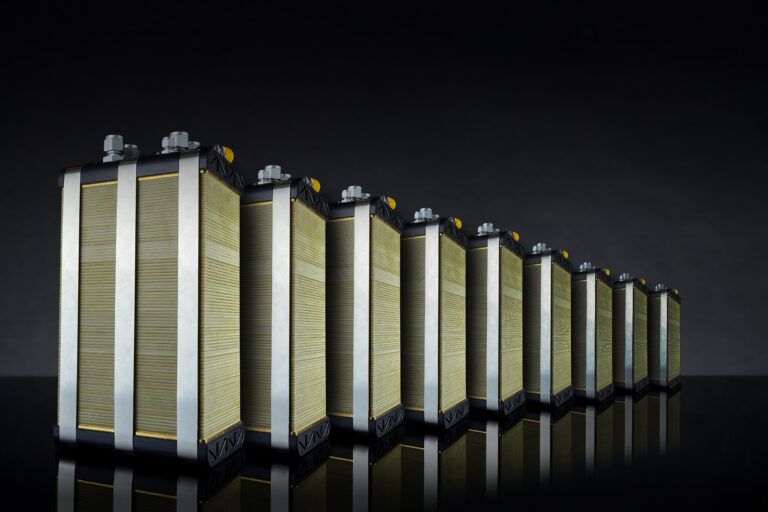

The project between Bramble and EDAG Group, named FC-STORM, aims to create and showcase a design study of the 3D integration of Bramble’s cutting-edge hydrogen fuel cell system into EDAG’s storage platform designed for passenger and light commercial vehicles. With the limited space available within the skateboard platform presenting the biggest challenge, Bramble’s PCBFC has been selected due to its versatility to be manufactured to almost any size or arrangement delivering a high-power, flexible solution to meet the stringent requirements.

Bramble’s ground-breaking PCBFC solution will be digitally incorporated into EDAG’s customisable energy platform (adaptable hydrogen and battery energy storage quantities). The study will highlight the broad range of advantages that a combined fuel cell and skateboard solution offers, with its flexibility, sustainability and cost-efficiency combining to demonstrate the performance values of a fuel cell electric vehicle (FCEV).

“Our partnership with EDAG Group is a fantastic opportunity for us to showcase the vast array of benefits that our cutting-edge PCBFC offers and its potential to offer a sustainable and efficient solution for passenger and light commercial vehicles,” said Dr Tom Mason, Bramble Energy co-founder and CEO. “Through our collaboration with EDAG Group, we will embark on an in-depth feasibility study that will present the performance advantages of hydrogen fuel cells as a viable sustainable mobility solution, with resulting scalable lop level system architectures and vehicle simulation data helping to provide clear evidence. The results of this project will act as a platform for future projects, showcasing the significant benefits of integrating our fuel cell solution into an EV skateboard which surpass existing solutions.”

The high-power density, flexible form-factor and easy power output adaptation of the PCBFC is a key consideration in this partnership. The requirement for the project will be a power output of > 40 kW including batteries and hydrogen storage at 700 bar which can be scaled depending on customer selected geometry variables of the skateboard such as height and width. Further System benefits are harnessed by realising a high voltage fuel cell adapted to a typical vehicle voltage level (i.e. 400 V or 800 V) that can be cooled without the need for deionised water, enabling a highly integrated electric power supply for mobility which surpasses current technical standards.