BMW Group has inaugurated its new Aeroacoustics and Electric Drive Center (AEC) at the company’s Research and Innovation Center in Munich, replacing a wind tunnel that had been in operation for nearly four decades.

The facility houses what BMW describes as the world’s largest vertical acoustic wind tunnel, measuring nearly 100 meters in length, 45 meters in height, and 25 meters in width. The tunnel operates with a background noise level of 54.3 dB at 140 km/h, comparable to a quiet conversation.

“Quiet is premium,” says Daniel Böttger, Head of Complete Vehicle Development at BMW AG. “Our focus is on meeting the premium standards of our vehicles. An important part of this is acoustics — particularly for quiet electric models. The new wind tunnel enables groundbreaking advances in aeroacoustics research.”

The wind tunnel features a 25-square-meter nozzle cross-section and can generate wind speeds up to 250 km/h, allowing testing of large vehicles such as the Rolls-Royce Phantom and BMW X7. Its 4.5 MW blower can move up to 100,000 cubic meters of air per minute.

Advanced measurement equipment includes a 216-microphone acoustic camera that can locate sound sources with sub-centimeter accuracy, and a laser vibrometry system for measuring vehicle surface vibrations. The facility also incorporates an acoustic all-wheel drive roller dynamometer for analyzing wind and rolling noises under controlled conditions.

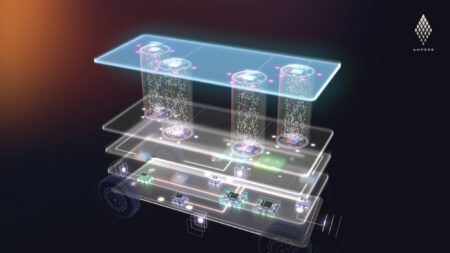

The second half of the AEC complex houses workshops, testing areas, and prototype production lines. This section includes 15,000 square meters dedicated to developing and testing high-voltage batteries for electric vehicles. An additional 800-square-meter clean room hosts a pilot line for manufacturing inverters, which convert direct current from batteries into alternating current for electric motors.

“The new AEC is another structural milestone for the BMW Group’s development of future mobility solutions,” says Dr Nicole Haft-Zboril, Head of BMW Group Real Estate Management. “To implement such a complex project in the shortest possible time, cost-effectively and with very high quality, there is a need for close integration between construction, development and production, as well as with all our partners and the City of Munich.”

The facility’s vertical design maximizes space efficiency on the site. Special acoustic isolation measures, including a three-meter-thick floor slab, protect the wind tunnel from external noise. The building’s multifunctional design allows for future reconfiguration to meet changing development needs.