The Volkswagen Group has announced the opening of a pilot line for advanced battery cell development, testing and production.

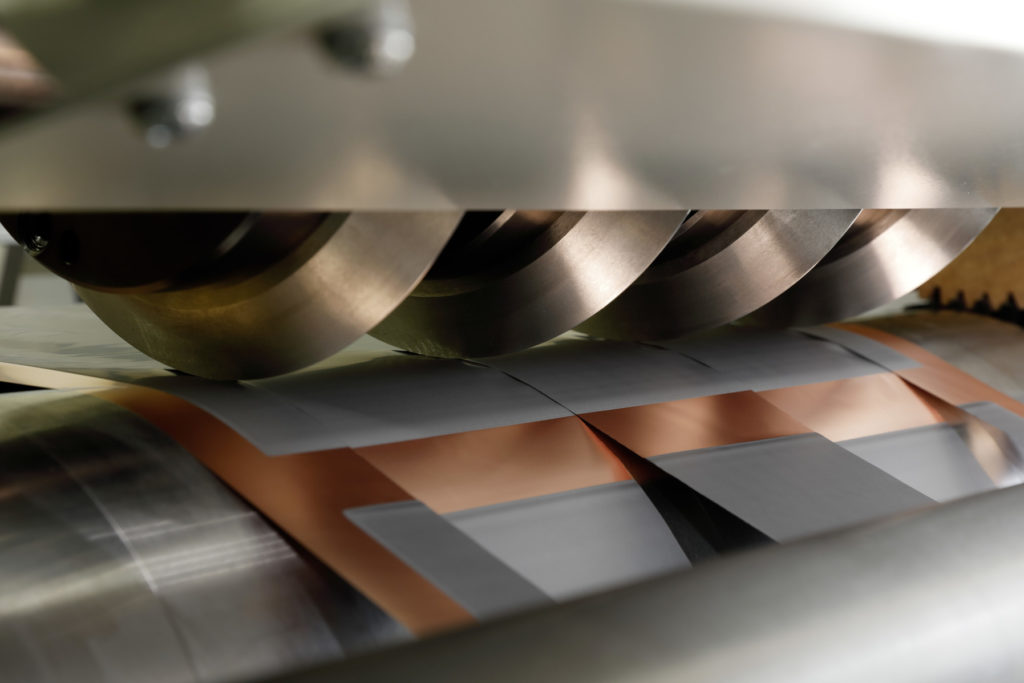

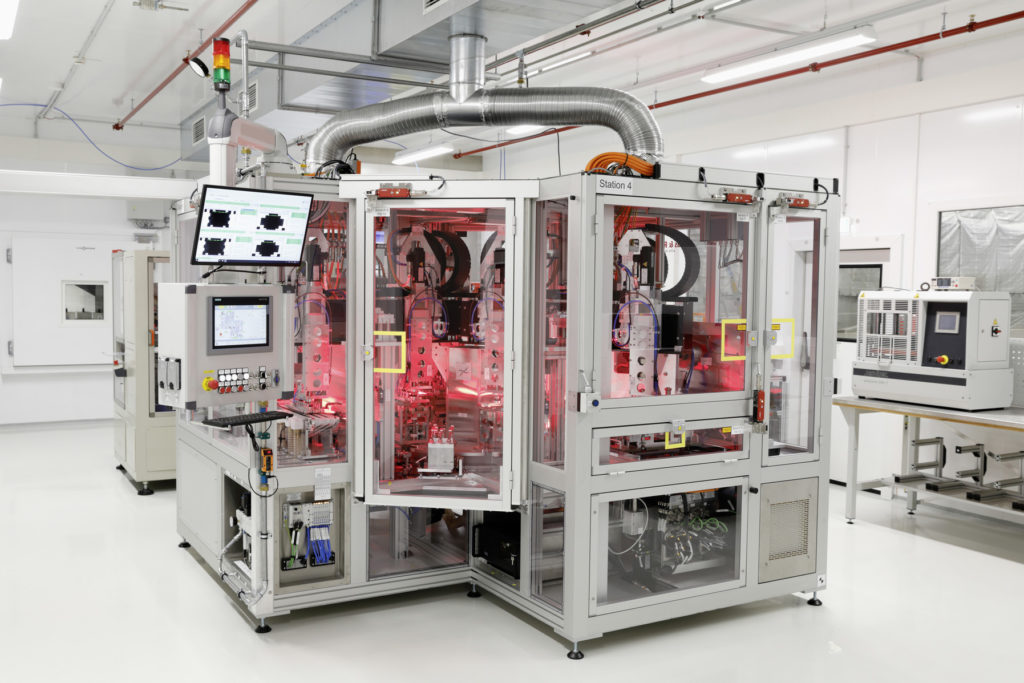

As part of a billion-Euro investment from the automotive manufacturer to develop and create its own battery cell know-how it has begun work at its Center of Excellence facility in Salzgitter, Germany. 300 experts will be on-site testing and piloting innovative manufacturing technologies for the production of lithium-ion batteries.

“Today’s commissioning of the pilot line is an important step on the road to building a gigafactory at the Salzgitter site. We will further deepen our knowledge of production processes within a short space of time. That is important in order to shape future developments and thus secure performance and costs as well as quality. The experience gained will also contribute to mastering the entire value chain for lithium-ion batteries – from raw materials through production to recycling,” said Frank Blome, head of the Center of Excellence for Battery Cells.

In addition, Volkswagen is also investing around €900m (US$982m) in joint battery activities with the Swedish battery producer Northvolt. Construction of a 16 gigawatt hour battery cell factory in Salzgitter is to start in 2020. It is planned to commence production in late 2023/early 2024. To that end, Volkswagen recently founded a 50/50 joint venture with Northvolt. 700 jobs are to be created in the medium-term in this independent joint venture.

“Bringing together the development, testing and pilot production of battery cells in Salzgitter marks a further milestone in the Volkswagen Group’s comprehensive electric offensive. By pooling know-how at this site, we are making sure we drive forward our own activities to further advance the development of battery cells as a key component in electrification, develop new standards and swiftly transition them to series production,” said Dr Stefan Sommer, member of the Volkswagen AG Board of management responsible for procurement.