Currently, 90% of batteries used for electric vehicles are being sourced from Asia, so to create competences and production capacities for Europe, a project has been launched that will see institutes and companies work together on the development of next-generation lithium-ion batteries.

The SeNSE project is supported by €10m and will involve five research institutes and six industrial companies from seven European countries working together over the next four years.

Coventry University’s Centre for Advanced Low Carbon Propulsion Systems (C-ALPS) is participating in the project, as well as Swedish company Northvolt, which intends to set up two large-scale production facilities (gigafactories) for vehicle batteries in Europe in the next few years.

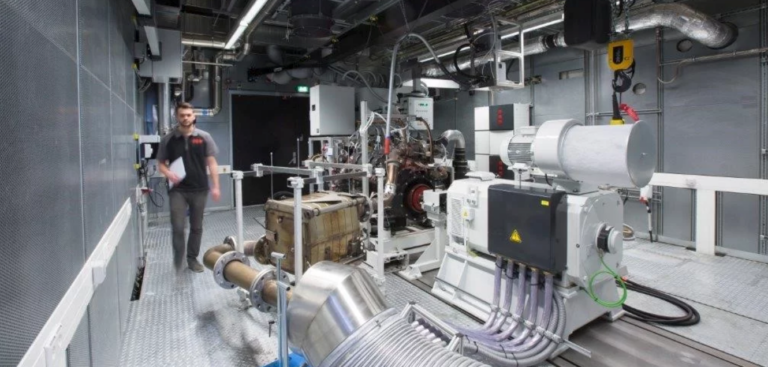

Also involved are: Empa, which is leading the project, the Westfälische Wilhelms-Universität Münster, the Forschungszentrum Jülich, the Austrian Institute of Technology, and the companies Solvionic, FPT Motorenforschung, Lithops, Enwires and Huntsman Advanced Materials.

The research in the SeNSE project is part of a European Battery Alliance initiative and is supported by the EU research funding program Horizon 2020. The eleven research partners of SeNSE are conducting research on next-generation lithium-ion batteries, called generation 3b. In contrast to current traction batteries, this next generation will have higher energy density and improved cell chemistry and battery management system: Instead of pure graphite anodes, the aim is to use silicon-graphite composites.

The content of critical cobalt in the cathode will be further reduced. New additives in the electrolyte and interphase design approaches will slow down battery aging and extend cycle life. New sensors will also contribute to a longer service life and improve fast charging capability by supplying data from inside the battery cells to the battery management system. This data should allow a much more refined temperature management compared to today’s lithium-ion cells.

The sustainability of generation 3b cells is also expected to exceed that of the current generation: The cathode will be manufactured without the use of flammable and toxic solvents, which will greatly simplify the series production of the cells and reduce their cost.

By the end of the project, a series of battery cell prototypes will have been developed, including a demonstrator with 1 kWh storage capacity to show the capabilities of the battery cell generation 3b.