As today’s vehicles become more electric and also electronic, there has been an increase in safety technologies with the rising addition of the number of sensors, screens, and driver assistance systems, which all adds greater complexity, cost and weight to the car.

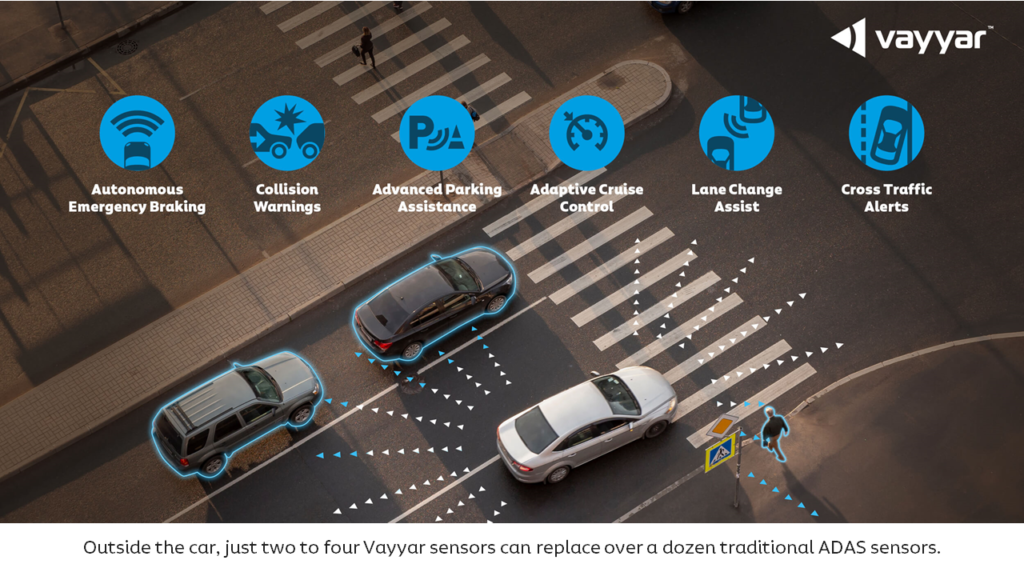

Vayyar Imaging, a specialist in 4D imaging radar technology, has created what it claims a breakthrough solution in vehicle safety with its Radar-on-Chip (RoC) platform – a single-chip that could replace over a dozen other sensors and negates the need for expensive LIDAR and cameras.

The chip features up to 48 transceivers, an internal digital signal processor (DSP) and microcontroller unit (MCU) for real-time signal processing. It can support a multitude of systems, including intruder alerts, child presence detection, enhanced seat belt reminders and eCall to alert emergency services in the event of a crash. It is capable of seeing through objects and able to operate effectively in all weather conditions.

Vayyar began by producing chips for a very different sector to automotive. It created a solution for breast cancer screening, which uses a portable device to produce a 3D image within 10 seconds without using an X-ray. Over the last five years, the company has been adapting and developing its technology for use within vehicles. Ian Podkamien, head of automotive at Vayyar, whose main focus has been leading the development teams on the RoC during this time, talks to Electric & Hybrid Vehicle Technology International about the potential of 4D radar sensor and its development process.

How have you seen electrification accelerate the development of sensors?

Vehicles are far more advanced than they were 20 years ago. What we have been seeing in general for today’s cars is an incremental need for both enhanced safety and improved user experience. They make so many driving decisions and perform so many functions such as seatbelt reminders etc. Then, on top of this, there’s the introduction of powertrain electrification which brings with it added complexities as there’s the strive for maximizing range and battery efficiency. Therefore, you cannot afford to have a heavy vehicle and you need to reduce any weight compared to an IC vehicle. Where this relates to sensors is that they all come with wiring, connectors and require power consumption. In-car monitoring systems, for example, can have hundreds of sensors and these all add to the weight of a vehicle, which is not efficient for an electric vehicle. This is becoming a significant challenge for the EV industry, so what we have seen is a drive for the consolidation of sensors to provide multiple functions to save on wiring, weight, and cost.

What is the approximate cost for the number of sensors in today’s vehicles and how can this change with a multi-function sensor?

There is research that tells us all the electronics within a vehicle adds around 35% to its overall cost. The expectation is that by 2030, this will increase to around 50% of the vehicle’s cost. That’s a massive cost. Our sensor will not be able to replace all of the sensors within a car, but it can take away several of them. On the sensor and wiring saving alone, this could be several hundred dollars – multiply this by potential millions of production units of any vehicle over the course of several years and you’re looking at a huge saving.

Have there been any specific regulation or legislation changes recently that have affected the development of sensors?

First of all, there is a big drive from Euro NCAP to improve levels of safety which is leading to exponential growth in raising the bar on better and safer cars. In 2023, child presence detection will be highly scored and seat belt reminders on the second row. Not only is this push related to the driver and passengers but also other vulnerable road users and the outside world. For road users and pedestrians, it is now a much safer environment. Secondly, government and organizational legislation follow the Euro NACP legislation and transform their scoring system into laws. Both of these are becoming very stringent and advanced and are requiring the need for more solutions, often in the form of adding a new sensor to solve the problem. However, the next year there may be another legislation and the need to add another sensor, which means you end up with a huge number of sensors, as well as having to go through the whole process of development, testing and validation.

How does Vayyar’s technology work?

Our credit card size sensor uses a 4D, high-resolution point cloud that can map the entire vehicle cabin into 5cm pixels, which is able to see the shape of every passenger as well as how they are seated, how they are moving, etc. So, with this, if there is the need to have a child presence detection regulation, you can derive out of the data if it is an empty car, or whether there is a baby inside and you can create an alert and tell the car to open the windows and turn on the climate control. What this rich data set enables us to do is have a platform that can react to any new legislation quickly, delivering OTA software updates, which can save any integration, testing and validation time and cost.

Traditionally, radars on cars are found on the outside but we are bringing the radar inside for in-cabin monitoring. Usually you need to develop the low-level radio frequency management, the algorithms, the filtering, which are all very intensive.

With the Vayyar chip we provide a full reference design, including antenna and array design so customers do not have to involve multiple vendors.

How will autonomous vehicle cabins present a challenge for sensors?

If, in the future, we are to be seated facing each other and drivers are looking intermittently at the road, the whole cabin environment will be dynamically changing so there needs to be optimized passive safety to adapt to what’s going on inside the car.

How did you test and validate the technology?

Over the years we have performed thousands of physical test cases. We’re not doing crash testing, but we have compiled a huge database using real humans, not dolls or emulators. Participants have been of all ages – even as young as a five-day-old newborn – sitting in all positions and the inclusion of many different baby seats. This has created a robust 4D point cloud data set that allows us to do any development on top of it, which would be able to fit the upcoming 2023 Euro NCAP scoring for child detection.

Will the RoC platform shorten the time to market for new vehicles?

We have intensively validated the performance of the sensor chip to meet automotive-grade criteria, as well as all of its components. Therefore, integrating it into new car models means there is no risk of delaying a launch due to coming across unforeseen problems. Also, the overall production cost is minimized, which is a big factor for OEMs.