As electric performance brand Polestar prepares to deliver the first of its Polestar 1, it has opened a brand-new manufacturing facility in Chengdu, China, that boasts futuristic, environmentally-friendly design and even a test track on-site.

Polestar, which was a spin-off from Volvo and is now recognized as a stand-alone vehicle OEM, has launched its brand into the world’s largest EV market with an innovative manufacturing space created by renowned architecture design company Snøhetta.

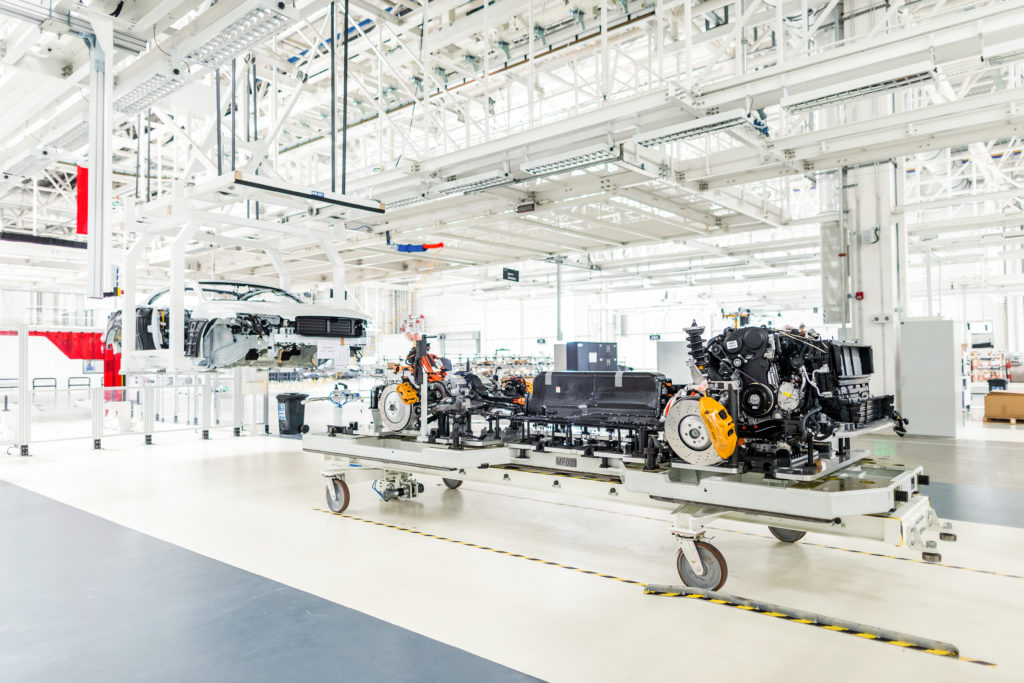

The new Chengdu production facility incorporates a customer experience centre including a test track and a glazed atrium offering a panoramic view over the factory floor.

“Designing Polestar’s first production facility has been a challenging and extremely rewarding project for us,” said Snøhetta’s co-founder, Kjetil Trædal Thorsen. “The innovative design of the interaction scheme aligns creative visionary processes with technical production requirements, setting a new standard for inclusive fabrication facilities.”

Images released of the facility show a clinically clean production area where workers intricately work alongside robotics.

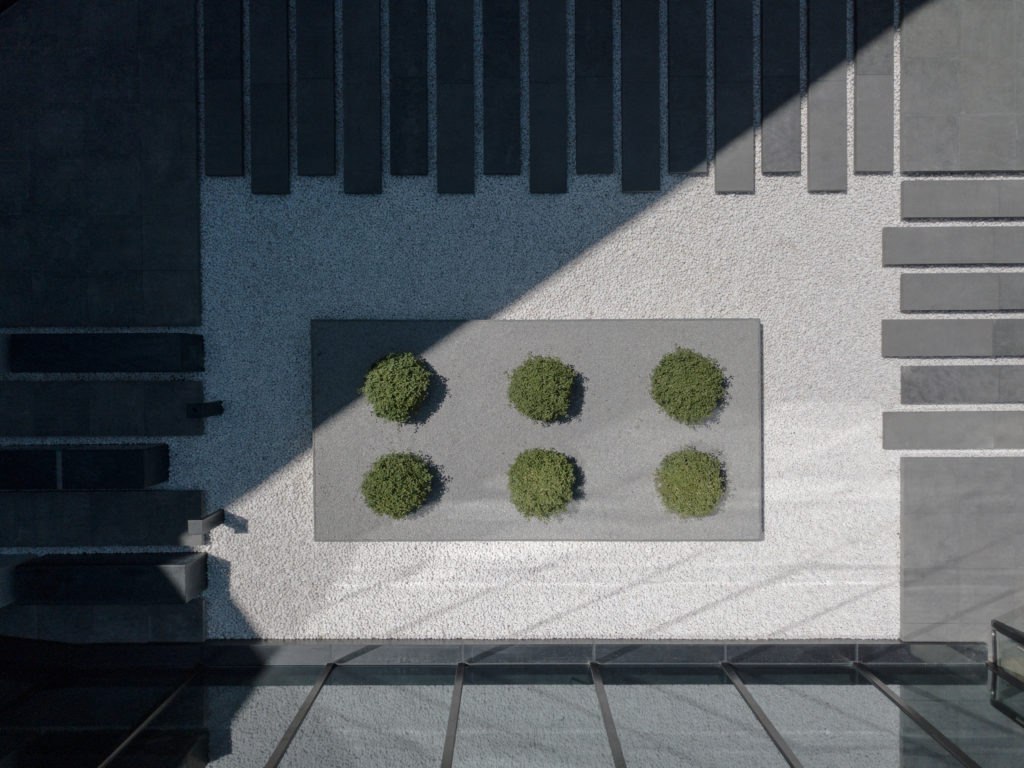

On the exterior, its sweeping and curved frontage is made of glass and dark metal, with ornate quiet areas spaced around.

The facility’s location in Chengdu – the heart of China’s most technologically advanced, environment-friendly manufacturing base – is also integral to Polestar’s brand values of ‘pure, progressive, performance’: pure in its focus on sustainability, progressive in both design and technology, and showcasing performance through its exacting and precise manufacturing processes.

The Polestar Production Centre aims to be one of the most environmentally responsible car factories in China. In keeping with these ambitions, and expected later in 2019, the facility was conceived with the goal of achieving Gold status in the globally-recognized LEED ratings (Leadership in Energy and Environmental Design).

“Here in Chengdu we are not only manufacturing a premium hybrid-electric performance car. We have also created an inspirational manufacturing environment, a great place to work and visit. It truly reflects the Polestar brand,” said Thomas Ingenlath, chief executive officer of Polestar.

The facility, which reinforces China’s maturing industrialization of EVs, is set to produce five hundred Polestar 1 cars per year, with 1,500 planned over three years. The first deliveries of the Polestar 1 are expected before the end of 2019.