REE Automotive (REE), an e-mobility innovation company, has revealed five new designs to its EV platform technology to support a broad range of commercial electric vehicles.

REE intends to provide a comprehensive range of technical configurations to fulfill specific B2B customer needs, including EV platform size selection based on preferred length, width and vehicle height; front, rear or all-wheel-drive with peak motor power ranges of 35 to 200 kW; front and all-wheel steer; advanced suspension capabilities; payload capacities of up to 5,000 kg and more.

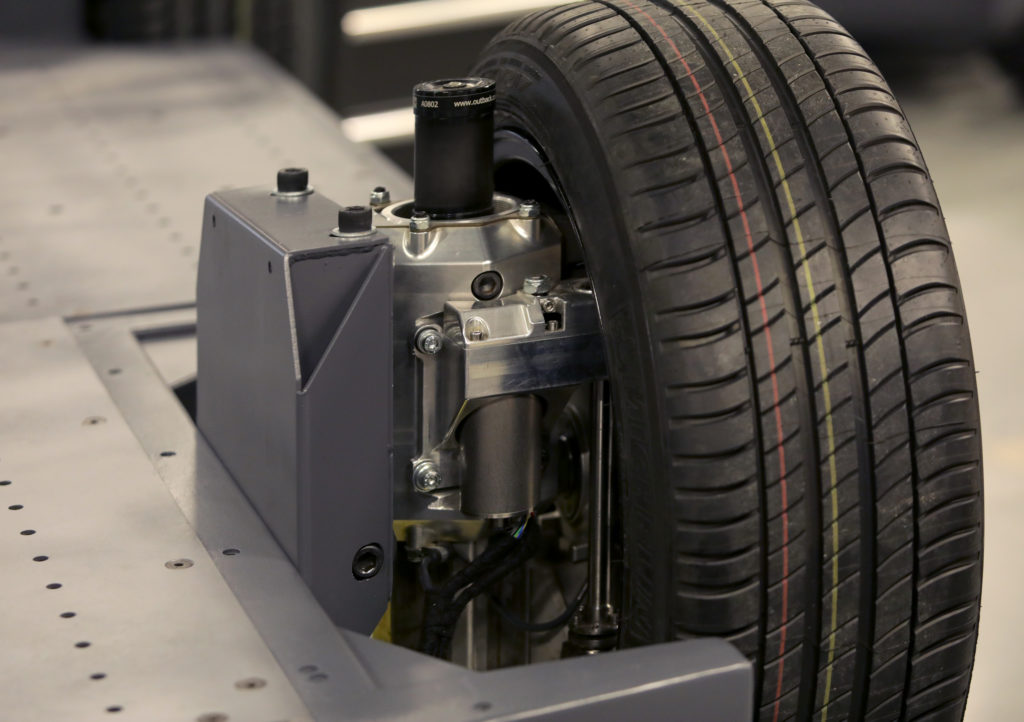

REE’s proprietary REEcorner technology contains critical vehicle components into a single compact module positioned between the chassis and the wheel – including steering, braking, suspension, powertrain, and control – resulting in a fully flat EV platform. REE’s fully flat EV platforms are designed with a lower center of gravity than vehicles with the motor located in between the wheels, and are intended to carry more passengers, cargo and batteries. REE’s smaller footprint and lower center of gravity will also allow for taller cabin designs and lower step-in height, yielding more volumetric efficiency.

“A bold new era for mobility demands a bold reimagining of what a vehicle can and should be, and that’s what we’ve done with REEcorner and our revolutionary EV platforms” said Daniel Barel, REE Co-Founder and CEO. “We believe that REEcorner technology will enable new EV platforms and designs to be adopted at lower costs and with faster development times than conventional EV skateboards.”

It is claimed that by adopting REE’s platforms, Mobility-as-a-Service providers can be empowered to build front-wheel drive e-shuttles with maximum payload capacity for transporting passengers with minimal kWh consumption. Conversely, logistics companies will be able to choose low-speed, all-wheel drive, all-wheel steer REEcorner configurations for last-mile delivery, with low step-in-height and minimum turning radius for easy maneuverability in congested urban streets. The technology can offer commercial delivery vans with low center of gravity, 360-degree all-side accessibility and unrestricted visibility for easy loading/unloading in docking stations.

Ahishay Sardes, REE Co-Founder and CTO, explains REE’s differentiation: “Unlike in-wheel motor systems, the motors in REEcorners are fully sprung masses, positioned on the chassis side of the suspension. By minimizing unsprung mass, REEcorners are designed for optimal ride and handling vehicle dynamics. REE’s plan to utilize true x-by-wire technology to control each of the corners of the vehicles with full drive-by-wire, brake-by-wire and steer-by-wire technology is expected to deliver vehicle stability, responsiveness and safety with fully independent wheel control. REE’s design further includes the REEcenter ECU (Electrical Control Unit) system to coordinate all four independent REEcorner ECUs, a thermal management system, power converter and power module. We believe that future customers who choose to build their electric vehicle fleets leveraging REE’s technology and EV platforms will benefit from significant operational and functional benefits over conventional EV fleets.”

REE’s technology is designed to offer EVs and AVs more space for passengers, cargo, and batteries. REE expects that electric vehicles built on REE’s EV platform will offer up to 35% more interior space than comparable commercial vehicles of similar size, providing much more room for cargo and goods and thereby necessitating fewer delivery routes for reduced carbon impact. Furthermore, REE’s smaller footprint saves valuable space in warehouses and parking areas, while allowing for easy maneuverability in crowded zones.