The innovations of electric vehicles (EV) have been taking monumental leaps in global interest as the importance of CO2 emission reduction is scrutinized by the Environmental Protection Agency (EPA). At this time of age, the world has been progressing towards building a society where technology is green, eco-friendly, and sustainable. As the automobile industry is making progress towards the new age where EVs will become the next big thing as they will overshadow internal combustion engine (ICE) vehicles and presumably dominate the world’s roads, a new set of lubricants and oils must be made specifically to tailor to the performance requirements of the electrical and gear components in the EVs.

Tribological performance testing for EVs is conducted to evaluate and further understand the characteristics of these advanced lubricants. The current and future developments of EV lubricants have a common goal to minimize friction loss, enhance durability, bolster efficiency, and strengthen other performance aspects. Satisfying those salient goals for EVs would pave the way towards a greener future.

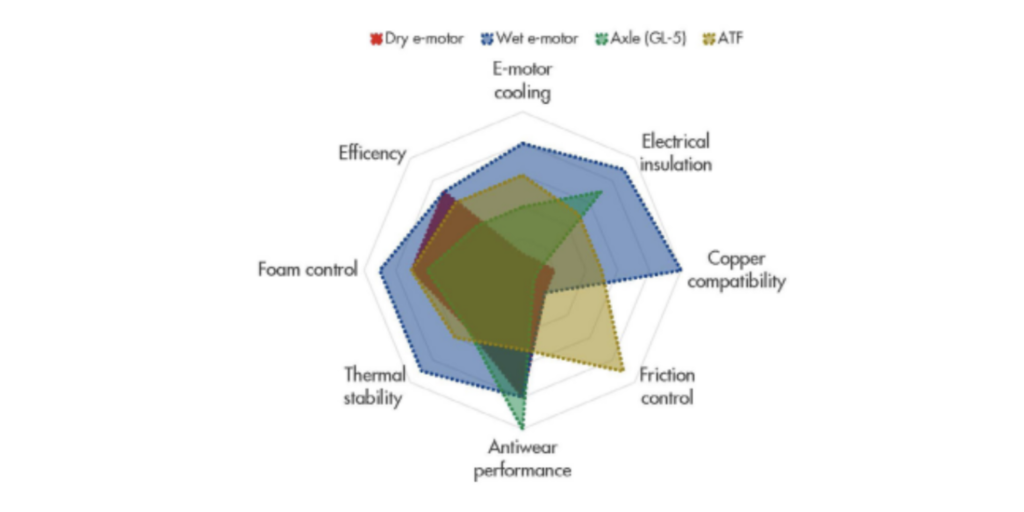

Creating lubricants for EVs is a difficult endeavor as original equipment manufacturers have their own unique electric motor design, thus requiring a specific lubricant for their electric motors to fit their needs for great performance. EV lubricants have greater technical requirements compared to that of ICEs. The lubricants must target important specifications such as antiwear performance, friction reduction, efficiency, electrical compatibility and insulation, and electric motor and battery pack cooling. EVs require lubricants in vital electrical components such as coolants for the car battery, gear oils for differentials, chassis, gear reducer, and wheels, brake fluids, and grease for other components of the EV. The difference the high-performance lubricants make for EVs can be shown in Figure 1. The overall performance output is greater when EV lubricants are applied to wet electric motors as compared to ATF.

Efficiency is an important area of focus and correlates directly to the torque properties of EVs and translate into range. Since electric motors are designed to be compact to save weight and space, higher rotational speeds of up to 18,000 rpm must be dealt with. When there is high stress occurring on the motor, air can infiltrate the components and cause fluids to foam which causes damage to the components’ surfaces. Therefore, reducing torque through the development of low viscosity lubricants will help solve those issues and push EVs to dominate the automobile industry. However, the formulated greases must refrain from altering mechanical properties such as tensile strength and crack resistance which requires many trial tests to balance the properties.

Other than making specific EV lubricants for performance purposes, the developing lubricants must be compatible with the electrical components of EVs such as electric modules, cable insulations, sensors, and circuits. The electric motor generates heat that must be insulated from the electric modules. Myriad cooling concepts and thermal management requirements will need to be considered when developing a compatible lubricant. The most popular lubricants today include mineral-based oils with different additives and synthetic-based oils due to their improved lubricity and thermal and oxidative stability.

Besides EVs, the growth of hybrid electric vehicles (HEV) also requires dedicated lubricants. With a smaller combustion engine alongside an electric motor, there are concerns regarding heat and aging stability. To create a viable lubricant, strong insulation properties are essential.

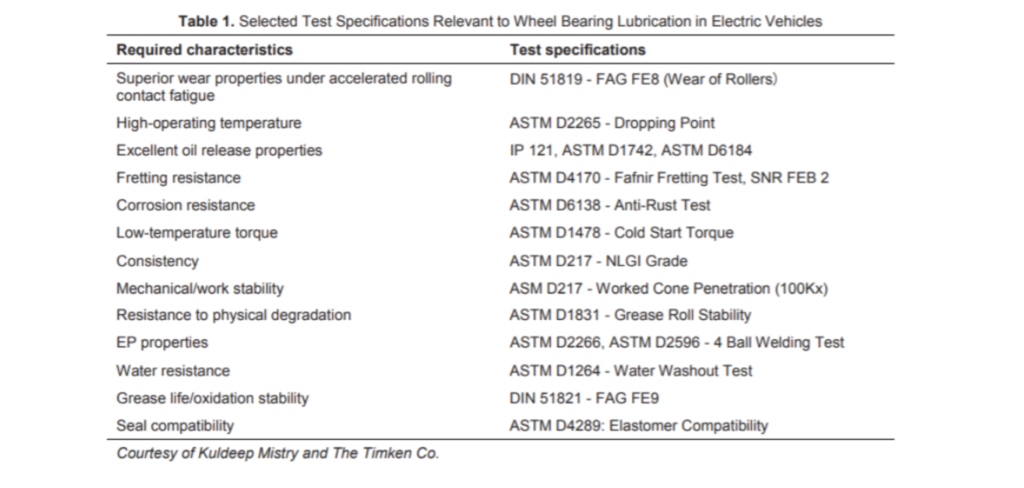

Various lubricant tests are performed to ensure specifications are met for EVs and HEVs. Oil viscosity is developed according to load, speed, and operating temperature of the application. While viscosity should be reduced to minimize friction loss, too low of a viscosity hinders durability and causes the lubricant to leak out of the vehicle’s bearings. This brings oxidation properties and dropping point to play when undergoing extreme temperatures. Additives are added to modify these properties, but some additives may be counterintuitive and may shorten the life span of the grease. Lastly, the lubricant must maintain electrical properties such as volume resistivity, dissipation factor, and dielectric strength to avoid electrical losses in the system. Overall, the lubricant must be formulated to balance all these requirements. Table 1 depicts specific properties that must be tested.

Other screening methods of the lubricants are used to ensure that a broad range of performance requirements are met. Methods such as copper wire corrosion testing, high-speed foaming testing, dielectric strength and breakdown, electrical conductance and impedance, and technology for high-speed driveline test rigs. These methods are used for both dry and wet electric motors. For EVs with wet electric motors, lubricants must be able to lubricate the gearbox and cool the electric motor.

Lithium greases have been ubiquitously used as lubricants for ICE (internal combustion engine) vehicles due to their many beneficial properties such as high dropping point, corrosion protection, and moisture resistance. Lithium greases can commonly be used in EVs for lubricating door locks and hinges and its powertrain. However, with the inclusion of an electric motor, dedicated lubricants need to fulfill different requirements for properties such as lower noise level. Additionally, electrical fields and currents generated from magnetic fields impact on the tribocontacts.

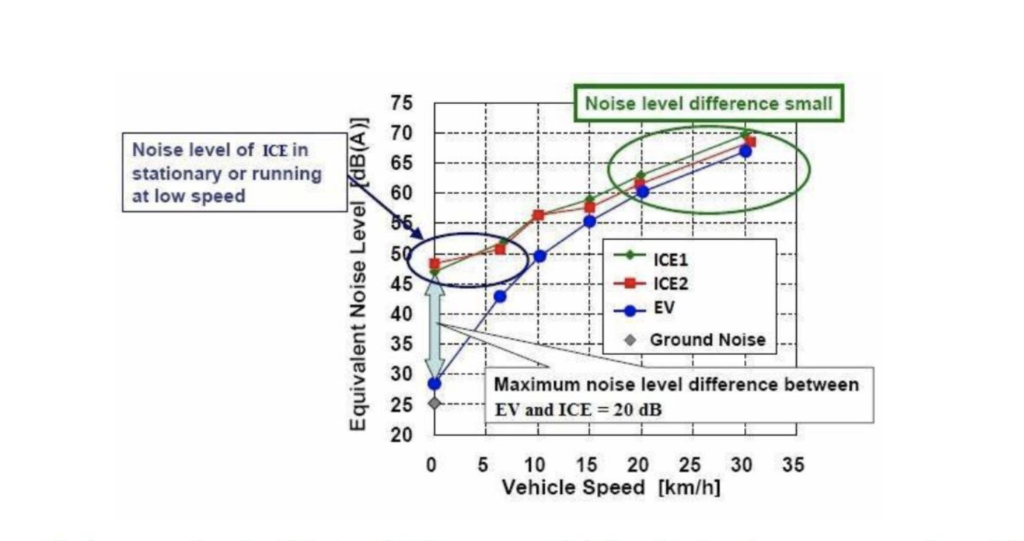

Vehicle noise derives heavily from the engine of ICE vehicles and poses danger to human safety. Excessive noise can cause hearing damage and cardiovascular diseases. Electric motors are steadier and produces less noise than ICEs but require an appropriate grease to mitigate the issue of excessive noise. As shown in Figure 2, the noise difference between ICE vehicles and EVs are significant especially at stationary or low speeds. The difference is important to note as many vehicles in the city are driven in that speed range.

The key question for EVs is, what is more crucial: low friction for range or cooling of the batteries for safety and fast charging? Hydrolubes, a mixture of water thickener by polyalkylene glycols (PAGs), were shown to offer high load carrying capacities and low friction for the gears. In a monofluid concept in the vehicle, hydrolubes can additionally cool the batteries.

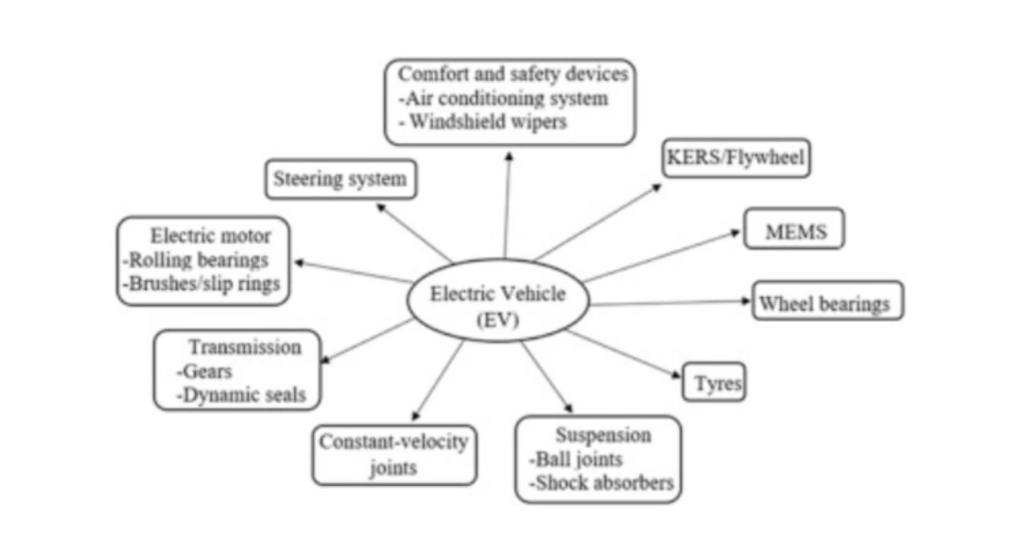

Many exotic proposals to enhance the trbiological profile of lubricants are under evaluation. Recent research for the development of EV oils and greases incorporates nano technology (carbon nanotubes and nanoparticles as well as graphenes and two dimensional MXenes) to strengthen the product. On top of nano technology, the addition of synthetic oils and titanium complex thickeners have been viable in reducing friction torque and increasing the lifespan of greases. More specifically, sulfur and phosphorus gear oil additives are commonly used to lower viscosity. Recently, spherical alumina nanoparticles have been tested to aid friction reduction as well. Other than incorporating additives and polymers, laser surface texturing has been implemented to coat the gears. The coatings are made of double-glow plasma surface alloying W–Mo [94], WC/C, WC/C–CrN, MoNx, DC and plasma nitriding and have shown impeccable tribological behavior [6]. As for corrosion protection, boron compounds have been promising in enhancing antiwear and extreme pressure properties as well as oxidation and thermal stability. Figure 3 illustrates a myriad of tribo-components to monitor.

With growing concerns regarding the environment, biodegradability is a trending development. Bio-lubricants is a prominent development for an accelerated biodegradability and can be incorporated into the making of EV fluids for a more environmentally friendly approach. Bio-lubricants used as resources of mainly animal fats and vegetable oils, which have unsaturates. They are effective alternatives to mineral oils due to their physicochemical properties. Bio-lubricants, like saturated esters and polyalkylene glycols, have shown to display better lubricity properties than mineral or synthetic oils because of the oxygenated backbone. Their functional profile for EVs can be alleviated through the addition of nanoparticles or advanced polymers such as rubber, polypropylene, and methylpentene which all showed promising results in high-speed applications.

Additives, such as antioxidants and pour point depressants, and chemical modifications such as transesterification and epoxidation, have also contributed to alleviate those issues. Currently, the most successful additives for high load greases include 3% MoS2 and graphite. Future prospects for bio-lubricants include microalgae and non-edible oil seed crops as resources, specifically, Jatropha curcas, Calophyllum inophyllum, Pongamia pinnata, Hevea brasiliensis (rubber seed), Ricinus communis L. (castor), and Simmondsia chinensis.

As EV are becoming more mainstream and are slowly integrating into our society for a greener world, dedicated EV lubricants follow ever so evidently. However, these lubricants are still in development stages which brings uncertainty for the future. With the stable growth in lithium greases, dedicated lubricants will be challenged as well. However, growing optimism and the strong push for environmental friendliness makes the development of EV lubricants more of a reality than mere pipe dream. The question now is when will these lubricants be developed and how grandeur will EVs prosper. After a boom in EV sales from 2011-2018, the sales decline and a recovery is awaiting.

This article was written by:

Dr Raj Shah, director at Koehler Instrument Company

Hillary Wong and Anson Law, chemical engineers at Stony Brook University

Dr Mathias Woydt, managing director of MATRILUB Materials, tribology, lubrication