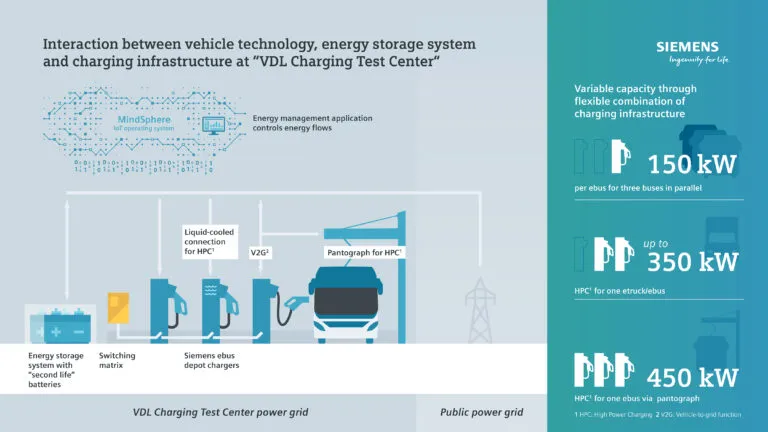

The ability to support the growing truck and bus electrification movement will rely heavily on its charging infrastructure, which is why Siemens is conducting trials using future-orientated technology at a dedicated test center.

Siemens is collaborating with Dutch bus manufacturer VDL Bus & Coach to come up with innovative solutions for depot charging of electric buses and trucks and is testing the latest generation of fast charging stations in real-life conditions.

The testing is taking place at the VDL Charging and Test Center in the Netherlands where the charging stations will work alongside a battery storage system, and to test and validate the interoperability between different OEM technologies.

“The charging technology from Siemens allows us to test different eBus and eTruck technologies in combination with charging stations and an energy storage system,” says Menno Kleingeld, managing director at VDL Enabling Transport Solutions. “With the energy management application we can control the flow of energy as needed. We also use second-life batteries in the storage system, which means we can re-use our earlier eBus batteries and give them a new lease of life.”

The vehicle-to-grid function integrated in one of the charging stations allows the vehicles to be charged bidirectionally. This means they can not only draw power from the grid and the storage system, but also feed energy back into these systems. This function paves the way for future use cases such as covering peaks in power demand. This means, electric vehicles are able to communicate with the grid and provide power back in case of capacity constraints.

A modular charging infrastructure system is also being used where charging systems can be expanded over time by coupling charging stations without the need to adjust grid capacity or connection.

“Three of our latest 150 kilowatt (kW) fast charging stations are being used in Valkenswaard. The charging electronics can be temporarily interconnected, making it possible to charge three vehicles in parallel with a capacity of 150 kW each, or one vehicle particularly rapidly up to 450 kW using High-Power Charging (HPC). This means power can be adjusted flexibly and the charging infrastructure optimized for depots with different requirements,” said Monique Mertins, head of charging infrastructure for eBus and eUtility Vehicles at Siemens Smart Infrastructure.