How 3M battery solutions can help EV battery designers address the challenge of vent path management

As EV battery design continues to evolve, so too do engineering challenges when mitigating thermal runaway propagation. Cells within an EV battery depend upon stable conditions to function properly – if temperatures exceed a critical limit, the risk of thermal runaway increases. At best, thermal runaway events can destroy a battery that isn’t well vented, as cell-to-cell propagation can spread rapidly, while gas buildup can simultaneously reach dangerous pressures. At worst, overheating due to thermal runaway can cause an explosion.

What is vent path management?

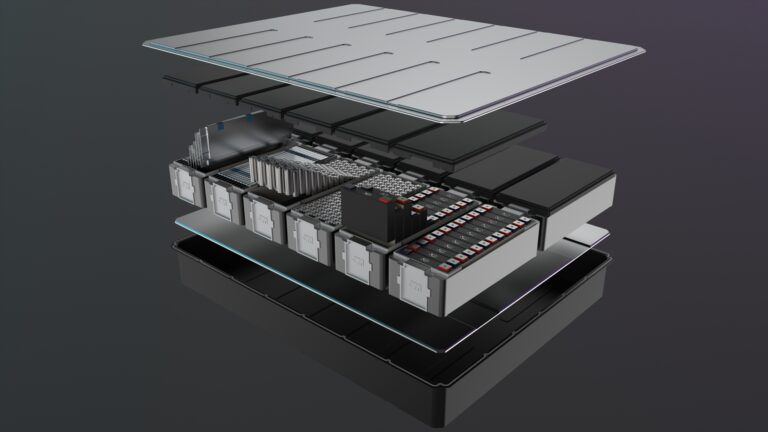

Vent path management is a critical strategy in mitigating risks from thermal runaway and maintaining the integrity of battery packs. There are several components to effective vent path management including helping to release heat and debris and providing thermal insulation when a battery cell experiences a thermal runaway failure.

Controlled venting is one of these components, as it involves directing flame and gas so that they are channeled through specific exit points in the battery pack to help battery designers address uncontrolled bursts. Alongside this, localized electrical and thermal insulation offers shielding from heat and debris near critical components such as electrical connectors or adjacent cells.

Advanced materials are needed at the foundation of these strategies to support vent path management in high voltage lithium-ion batteries, which are vulnerable to thermal runaway risks such as ejected flames, particles and gases that can damage adjacent cells or flammable materials. Flexibility and customization across the battery pack are just as important as the materials and components employed, and manufacturers must consider the challenges of their own unique battery and vehicle design.

The challenges

While the objectives of vent path management are simple, the obstacles to achieving it are not. Designing an EV battery pack that provides reliable performance and holds up in extreme conditions is challenging. Take the physical conditions of thermal runaway event: temperatures can exceed 1,000°C which quickly degrades materials and compromises vent paths while also risking cell-destroying flame propagation. In addition to extreme temperatures and flames, pressure release of gas and particles can damage components and cause short circuits as well, creating unfavorable conditions.

Underlying these unique challenges are the inherent constraints posed by the limited space within a battery pack. Effective vent path management demands innovation to create a compact solution that stands up to extreme conditions. How can manufacturers accomplish this? Let’s take a look at how 3M material science can help battery designers address certain challenges.

Tackling the challenges

3M, through exhaustive testing and experimenting, has led innovation in advanced vent path protection materials, providing OEMs with solutions to address design challenges in EV battery pack with limited space. Key to their success is developing products made of advanced materials that offer temperature stability with powerful thermal insulation when under great stress, helping to protect cells and neighboring components from heat and energy released in thermal runaway events. When these materials are strategically placed, it becomes much easier to isolate high velocity ejected gas from critical components including the battery lid and adjacent cells.

Most importantly, 3M understands that vent path management demands a range of choices in material properties. Products include tape that covers electrical connectors and sensitive components for direct shielding from ejected materials, enclosure barriers applied over or underneath cells to help redirect hazards, and silicone-based materials that allow for venting and help maintain mechanical integrity. Many of these materials are designed with strong adhesive properties and conformability to complex shapes – helping battery designers to protect the most critical and sensitive components within a pack.

3M vent path management solutions can help battery designers address challenges such as how to incorporate vent path management with products that have high temperature and flame-resistant properties to help shield components during the release of flames, particles, gas and smoke. 3M also offers customization for the toughest design challenges.

The future of EV battery design

The demands for creative EV battery design solutions are not slowing down any time soon, and neither are the experts at 3M who work to anticipate the next set of industry challenges. With established expertise in battery technologies and extensive battery material testing capabilities, 3M experts are ready to collaborate with you to identify a barrier solution for your needs.

3m.co.uk