As the automotive industry shifts towards electric vehicles (EVs), safety concerns have prompted Chinese lawmakers to introduce the GB29743.2 standard. This regulation mandates a significant reduction in the electrical conductivity of coolants to enhance battery safety and prevent leaks. To understand this regulatory change, we interviewed Sander Clerick, Development Chemist, and Guillaume Vanpeteghem, Area Sales Manager, from Arteco, a global leader in engine coolant solutions. Their insights highlight the standard’s impact on the global coolant market and the necessary adaptations for compliance.

How is Chinese legislation driving changes in the coolant market?

Sander: Well, Chinese lawmakers have intervened following global incidents where engine coolants led to thermal runaway of BEV battery packs. This prompted the creation of a new battery system coolant standard, GB29743.2, aimed at enhancing safety in electric vehicles. The focus is on reducing electrical conductivity of coolants, with a proposed limit below 100 µS/cm.

What are the timelines of this change?

Guillaume: Development of the standard GB29743.2 began in 2023, will be submitted for approval in August and official publication is expected in August 2025. After this, a short implementation period of 6 to 18 months is proposed. So, we expect that all refrigerant suppliers and OEMs will have to comply with this standard by the end of 2025.

What does this mean for European & US OEMs?

Guillaume: The stakes are high, as non-compliance with GB29743.2 would mean exclusion of exports or sales in the People’s Republic of China. Other industry associations are working on similar specifications and OEMs are drafting their own, using GB29743.2 as a minimum requirement. Arteco is in close contact with all major OEMs to assist in this transition.

How can battery safety be improved by using water-glycol based coolants?

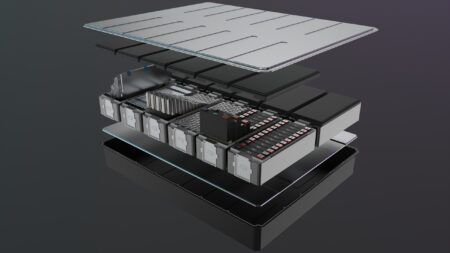

Sander: Lowering the electrical conductivity of coolants reduces the risk of overheating and battery discharge during a short circuit. By combining the low electrical conductivity of the coolant with a robust battery pack design, the failure of coolant leakage is eliminated. However, ensuring that other properties of the coolant, such as heat transfer and material compatibility, remain unchanged is crucial for maintaining safety standards.

How will this change affect the service model OEMs & service life of the coolant?

Guillaume: During the life of the coolant, electrical conductivity will increase due to contamination, incompatibility of materials or thermal stress. It is likely that OEMs will set a threshold value for electrical conductivity after which the coolant is no longer safe to use. At Arteco, we have designed our product to minimize the impact of contamination. Together with excellent corrosion protection and thermal robustness, this ensures a long service life.

How does Arteco as a coolant technology provider cope with this challenge?

Sander: At Arteco, we were already one step ahead by anticipating this safety requirement and launching a product with the desired electrical conductivity in 2022. We follow standard designs and developments closely, have the right products ready & (fleet) tested, are ready for the future ourselves & together with OEMs.

If you would like to know more about these regulatory shifts and our our solutions, subscribe for our upcoming webinar on the 23rd of September. Click here to subscribe.