Leading hydrogen fuel cell provider Bramble Energy has published a pivotal whitepaper identifying a clear path to creating the world’s lowest cost fuel cell – an innovation which will revolutionise the hydrogen economy and drive mass adoption across mobility and energy sectors.

The whitepaper reveals Bramble Energy’s solution to creating a $100 per kilowatt stack – ten times cheaper than current traditional fuel cell costs – and has identified it could reach as low as $60 at unprecedented speed to market as a result of scale. Dropping below industry price targets within such a game-changing timeframe will eradicate the high costs of fuel cell technology which remain the major barrier to wide hydrogen adoption, particularly in sectors such as transportation.

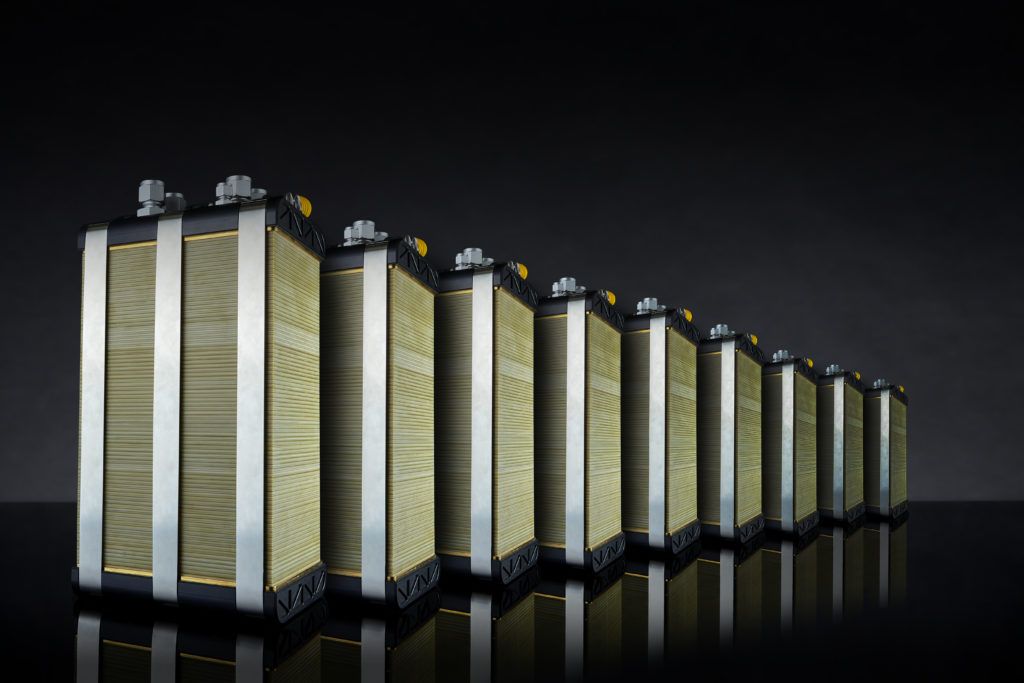

Current fuel cell technologies exceed $1000/kW, so it is a major leap to achieve $100/kW. The paper presents Bramble Energy’s ground-breaking patented printed circuit board (PCB) fuel cell technology to bring industry towards this goal through innovative design, materials selection, and manufacturing processes.

The company’s whitepaper highlights with manufacturing volume increases, achieving economies of scale in terms of purchasing power and optimisation of process flows it has the potential to achieve a PCB cost of $60/kW at 1.5 Wcm-2 power rating should production be in the hundreds of megawatts.

“Industries are in desperate need of attainable, sustainable, clean energy solutions, so our mission at Bramble Energy is removing the biggest barriers to hydrogen adoption,” said Dr Tom Mason, Bramble Energy co-founder and CEO. “With high cost hindering the hydrogen fuel cell industry for years, this whitepaper demonstrates how our printed circuit board fuel cell technology can deliver fuel cells at an achievable cost and the speed at which it be realised compared to existing technology. We hope this paper will provide industries from mobility to energy storage the encouragement for fuel cell technology to reach mass adoption as quickly as possible, and as a result, begin decarbonising immediately.”

Currently in early phase testing and in-work through its UK supply chain, short stack testing of this technology will be conducted in Q4 2023 after further core module optimisation; with full stack testing expected in Q2 2024.

The full whitepaper can be accessed here.