Equipmake, the UK developer and manufacturer of electrification products for battery-electric vehicle drivetrains, have unveiled its Ampere-220 e-axle system.

The compact, lightweight, high-power electric drive system for manufacturers of

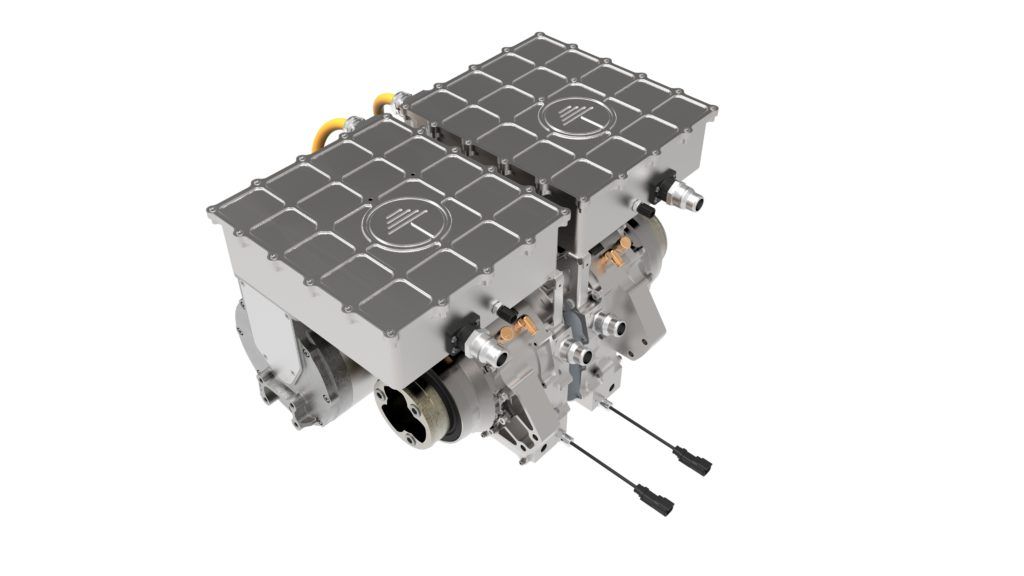

high-performance EVs was showcased at the Battery Show Europe, Stuttgart this week. It combines an advanced 3D-printed electric motor with all power electronics – including the company’s own silicon carbide inverter – as well as an integrated transmission system in a compact unit that directly powers the vehicle’s axle.

The e-axle features the Ampere electric motor, with a spoke rotor design which recently featured in the Ariel Hipercar and is extremely lightweight yet efficient. Ampere has peak power of 220kW and a maximum motor speed of 30,000rpm. Weighing just under 20kg, it offers power density of 11kW per kg – more than twice that of a conventional electric motor.

Rather than being milled from a solid billet, metal is only put where it is needed, while thermally efficient thin walls and optimised fine surface details are combined directly with the motor’s structure, replacing multi-part assemblies with a single, complex architecture that has exceptional cooling ability, is lightweight, has low inertia and allows for greatly increased rotational speed.

The advanced electric motor is combined with all necessary power electronics, including Equipmake’s high-performance silicon carbide-based inverter, and an integrated transmission system too, resulting in a highly compact and lightweight electric drive system, ready to be integrated into a high-performance electric vehicle. Debuted in twin-motor specification, Ampere-220 e-axle offers 440kW peak power per axle with a total unit weight of just 85kg.

“Equipmake has always been at the forefront of innovation in electric motors, with our APM range offering class-leading power densities thanks to their compact, lightweight designs,” said Ian Foley, Equipmake CEO. “Ampere showcases the next gen of motor technology. With such a huge amount of performance in a compact, light unit, one that is also ISO 26262-compliant and ASIL-D ready, it provides the total off-the-shelf solution for manufacturers of electric sports cars, further underlining Equipmake’s position as a leading provider of state-of-the-art electrification systems to the automotive industry.”

The Ampere-220 e-axle is designed, engineered, and manufactured at Equipmake’s headquarters in Snetterton, Norfolk, where the company provides the complete electric vehicle solution, offering everything from motors to fully electrified platforms, supporting primarily the automotive and aerospace sectors. On site, it designs and manufactures its fully integrated electric bus chassis for an increasingly international customer base.